1. Introduction

UV resin is popular in jewelry making and small craft projects because it cures quickly and creates a clear, glossy finish. However, not everyone owns a UV lamp, especially beginners or hobbyists just getting started. This often leads to a common question: how to cure UV resin without UV light when professional tools aren’t available.

The good news is that curing UV resin isn’t always limited to specialized equipment. Natural sunlight and certain alternative methods can sometimes trigger the hardening process, depending on the resin type, layer thickness, and environmental conditions. While these options may take more time and don’t always deliver the same level of consistency as a UV lamp, they can still be effective for small or simple projects.

In this guide, you’ll learn what actually works, what has limitations, and how to set realistic expectations when curing UV resin using non-traditional approaches.

Table of Contents

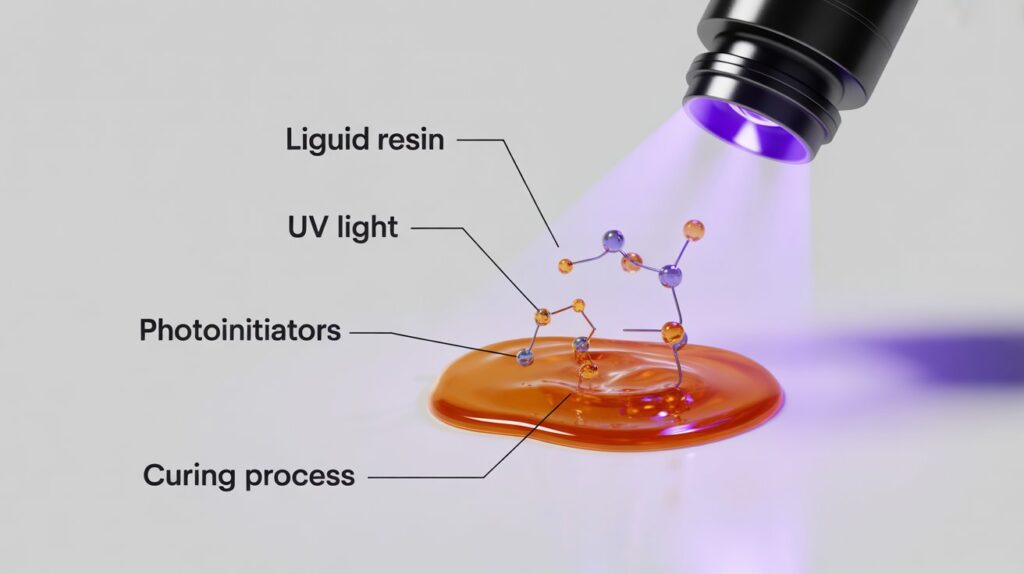

2. Understanding How UV Resin Hardens

UV resin hardens through a chemical reaction called photopolymerization. This process begins when the resin is exposed to ultraviolet rays, which activate special molecules known as photo initiators. Once activated, these molecules cause the liquid resin to link together and form a solid, durable surface.

Unlike epoxy resin, which cures through a two-part chemical reaction over time, UV resin remains liquid until it receives sufficient ultraviolet exposure. This is why it can stay workable for long periods and then harden quickly once exposed to the right light source. The strength and wavelength of the light play a major role in how well this reaction occurs.

Not all light sources emit the same type or intensity of UV rays. Some household lights produce little to no ultraviolet output, which can result in slow curing or incomplete hardening. Environmental factors such as light distance, exposure duration, and resin thickness also affect the final result. Understanding these basics helps explain why certain alternative methods work better than others and why some projects require more patience to fully cure.

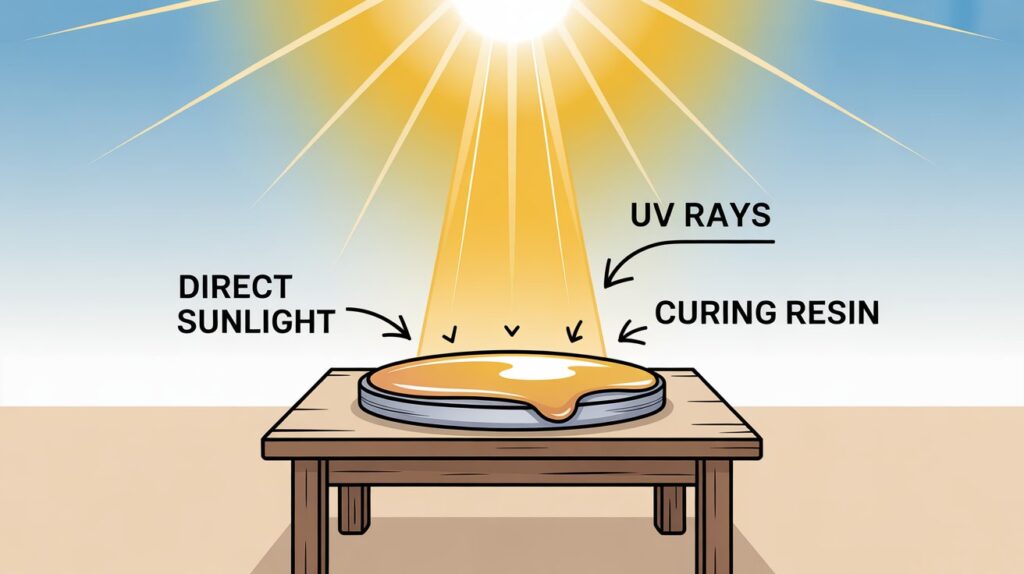

3. Sunlight as a Natural Curing Method

Sunlight is one of the most accessible alternatives because it naturally contains ultraviolet rays. When UV resin is placed under direct sun exposure, these rays can activate the resin’s photoinitiators and begin the hardening process. This makes sunlight a practical option for small projects when specialized tools are unavailable.

The effectiveness of sunlight depends heavily on conditions. Bright, direct sunlight works far better than indirect or shaded light. Midday sun usually provides stronger UV intensity than early morning or late afternoon, leading to faster and more even results. Outdoor placement is generally more effective than indoor exposure, as windows can block a significant portion of ultraviolet rays.

Curing with sunlight takes longer than using a dedicated lamp and may not produce consistent results every time. Thin layers tend to harden more reliably, while thicker pours may remain soft underneath. Even so, with patience and proper positioning, sunlight can successfully cure UV resin for simple designs and lightweight craft projects.

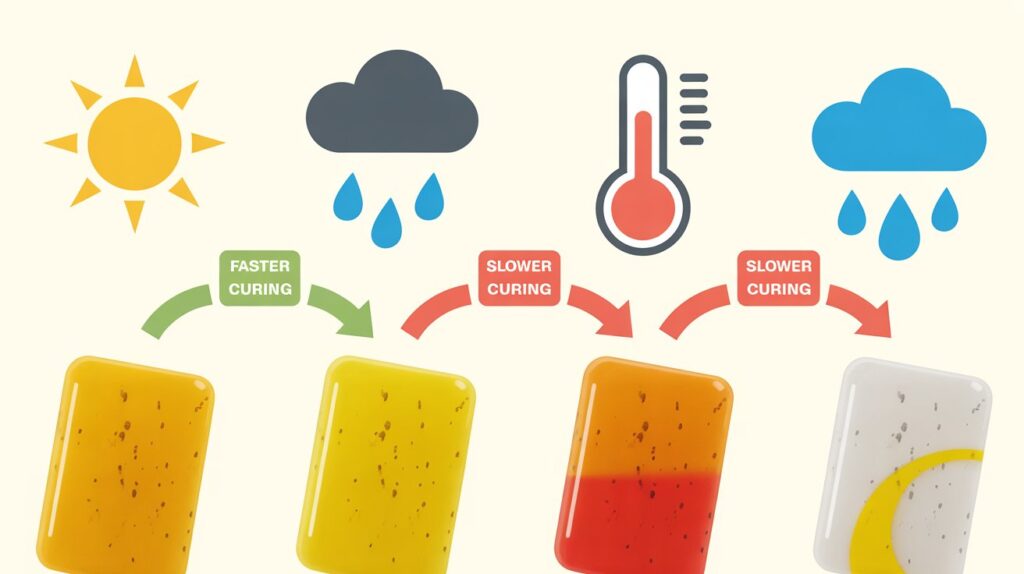

4. Weather and Environment Impact on Results

Weather conditions play a major role in how well UV resin cures when natural light is used. Clear, sunny days provide stronger ultraviolet exposure, while cloudy or overcast skies can significantly slow the hardening process. Even thin cloud cover can reduce UV intensity, leading to uneven or incomplete results.

Temperature also affects curing performance. Warmer conditions help the resin flow and react more efficiently, while cold environments can make it thicker and slow down the curing reaction. Extremely high temperatures, however, may cause surface defects such as bubbles or warping in molds.

Humidity is another important factor. High moisture levels in the air can interfere with surface curing, sometimes leaving a tacky or soft finish. For best results, resin should be placed in a dry, warm, and well-ventilated area with steady sunlight. Managing these environmental factors can greatly improve consistency and overall curing quality.

5. Glass Windows vs Direct Sun Exposure

Not all sunlight reaches UV resin with the same strength, and glass plays a major role in this difference. Most modern windows are designed to block or filter ultraviolet rays to protect interiors from heat and fading. As a result, sunlight passing through glass is often much weaker for curing purposes.

Direct outdoor exposure allows the resin to receive a higher concentration of ultraviolet radiation, which leads to faster and more reliable hardening. Placing projects outside in open sunlight typically produces better results than setting them on a windowsill indoors. Even clear glass can reduce the effectiveness enough to leave the surface partially cured or uneven.

If outdoor placement isn’t possible, positioning the resin near an open window can help, but curing times will be longer and results less predictable. For consistent outcomes, direct sun exposure without any barrier remains the most effective option when using natural light.

6. Using LED and Household Lights

Many crafters try to use common household lights as a substitute for specialized curing tools, but results can vary widely. Most standard LED bulbs, desk lamps, and ceiling lights are designed for visibility, not for emitting ultraviolet rays. Because of this, they often lack the UV intensity needed to fully harden resin.

Some LED sources, such as nail lamps or high-output LEDs, may emit small amounts of ultraviolet or near-UV light. These can sometimes partially cure thin layers, especially with extended exposure times. However, the curing process is usually slow and inconsistent, and the resin may remain soft or sticky underneath the surface.

Traditional incandescent and fluorescent lights are even less effective, as they produce minimal UV radiation. While household lighting can help slightly in combination with other methods, it should not be relied on alone for consistent or durable results.

7. Thickness of the Resin Layer

The thickness of the resin layer has a direct impact on how well it cures. Thin layers allow ultraviolet rays to penetrate more easily, leading to faster and more even hardening. This is why shallow pours and surface coatings tend to produce better results than deep or bulky designs.

Thicker layers can create problems because light may only reach the surface, leaving the interior soft or uncured. This often results in a hardened top with a flexible or sticky underside. In some cases, the resin may appear solid at first but deform over time due to incomplete curing inside.

To improve results, applying resin in multiple thin layers is a more reliable approach. Allowing each layer to harden before adding the next helps ensure proper curing throughout the entire piece and reduces the risk of long-term defects.

8. Time Requirements Compared to UV Lamps

Curing resin without specialized equipment requires significantly more time than using a UV lamp. A proper lamp can harden thin layers within minutes, providing fast and consistent results. In contrast, alternative methods rely on weaker or less direct ultraviolet exposure, which slows the process.

When using natural light or household sources, curing may take several hours or even multiple days, depending on conditions such as sunlight strength, temperature, and layer thickness. Frequent repositioning may also be needed to ensure even exposure on all sides of the project.

Longer curing times increase the risk of dust settling on the surface or uneven hardening. While patience can lead to acceptable results for small projects, the time difference highlights why UV lamps remain the preferred choice for reliable and professional-quality finishes.

9. Surface Stickiness and Oxygen Inhibition

A common issue when curing resin without a UV lamp is a sticky or tacky surface. This is often caused by oxygen inhibition, a natural reaction where oxygen in the air interferes with the hardening process. While the resin may appear solid underneath, the top layer can remain soft or slightly sticky.

The effect is more noticeable with thin layers or when curing under indirect light, as slower polymerization allows oxygen to react with the surface for a longer period. Using a protective cover, such as a clear lid or a piece of plastic wrap, can reduce exposure to air and help achieve a smoother finish.

Proper layer management also helps. Applying resin in multiple thin layers, allowing each to cure fully before adding the next, minimizes surface stickiness and ensures more consistent results throughout the piece.

10. Safety Considerations When Using Sunlight

Using sunlight to harden resin may seem safe, but there are several precautions to keep in mind. Direct sun exposure can generate heat, which may warp molds or cause resin to bubble, especially in enclosed or dark-colored containers.

Extended exposure to ultraviolet rays also poses risks to the skin and eyes. It’s important to wear protective gloves, avoid looking directly at the resin under strong sunlight, and limit prolonged contact with uncovered skin.

Additionally, placing projects outdoors may expose them to dust, debris, or insects, which can settle on the resin and affect the final finish. Choosing a clean, shaded, but well-lit area can help reduce these risks while still allowing the resin to cure effectively.

11. When Alternative Methods Are Not Enough

While sunlight and household light sources can work for simple or small projects, there are situations where these alternatives fall short. Large, thick pours or intricate designs often require consistent and intense UV exposure to fully harden. Using weaker light sources in these cases may leave the resin soft in the middle, resulting in warping, bubbles, or incomplete curing.

Professional-quality finishes, such as jewelry pieces with embedded items or complex molds, typically need a dedicated UV lamp to achieve durability and clarity. Relying solely on natural light or household LEDs may lead to inconsistent results and longer project times.

For crafters who plan to work on frequent or larger-scale projects, investing in a proper curing device ensures reliable, repeatable results and reduces the risk of defects caused by uneven or incomplete hardening.

12. Common Myths About Curing UV Resin

There are several misconceptions about hardening UV resin that can mislead beginners. One common myth is that any light source will work. In reality, only ultraviolet rays of sufficient intensity trigger the curing process, so standard household lamps or weak LEDs often fail to produce solid results.

Another misconception is that leaving resin out longer always fixes it. While extra time may help in some cases, insufficient UV exposure or thick layers can still result in a sticky or soft interior, regardless of how long the resin sits in indirect light.

Some people also believe that a tacky surface means the resin is fully cured inside. In fact, oxygen inhibition can leave the top layer soft while the underlying resin remains solid. Understanding these facts helps set realistic expectations and prevents frustration when using alternative methods.

13. Best Practices for Successful Results Without Tools

Achieving good results without specialized curing equipment requires careful planning and technique. Here are some best practices to follow:

- Work in Thin Layers: Apply resin in small amounts to ensure light can penetrate fully. Multiple thin layers cure more evenly than one thick pour.

- Maximize Light Exposure: Place projects in direct sunlight whenever possible. Rotate or reposition pieces periodically to ensure all surfaces receive adequate light.

- Choose the Right Time and Environment: Clear, warm days are ideal. Avoid curing during cloudy or humid conditions, which can slow the process or affect the finish.

- Protect Surfaces from Dust and Debris: Cover resin with a clean lid, plastic wrap, or a container to prevent particles from sticking while it hardens.

- Be Patient: Natural methods take longer than UV lamps. Check progress regularly but avoid disturbing pieces too frequently.

- Use Protective Gear: Gloves and UV-safe eyewear help prevent skin contact and reduce UV exposure when using sunlight for extended periods.

Following these strategies improves the likelihood of smooth, solid results, even when using alternative light sources or natural sunlight for curing.

14. Who Should Use These Alternative Methods

Alternative curing methods are best suited for beginners, hobbyists, or casual crafters who do not have access to specialized equipment. Small projects, quick experiments, or decorative items can often be completed successfully using sunlight or household light sources.

These methods are also helpful for people working in temporary or travel setups where carrying a UV lamp is impractical. Simple resin crafts like thin charms, pendants, or small embellishments are ideal candidates.

However, crafters who frequently create large, thick, or professional-quality pieces may find that alternative methods are too slow or inconsistent. In such cases, investing in a dedicated curing tool ensures faster, more reliable results and reduces the risk of defects.

By understanding the limitations and appropriate use cases, creators can decide when natural or household light is sufficient and when professional equipment is necessary.

15. Conclusion

Curing resin without a UV lamp is possible, but it requires patience, careful layering, and attention to environmental factors such as sunlight, temperature, and humidity. By understanding how light, layer thickness, and surface conditions affect the hardening process, crafters can achieve satisfactory results using natural light or certain household alternatives.

While these methods work well for small or simple projects, they may not provide the same speed or consistency as a dedicated UV lamp. For larger or professional-quality pieces, investing in proper equipment is the most reliable way to ensure a smooth, fully cured finish.

With the right techniques and realistic expectations, anyone can successfully explore how to cure UV resin without UV light and create beautiful resin crafts even without specialised tools.

FAQs

1. How do you cure UV resin without a UV light?

Use direct sunlight or UV-emitting LED lights. Thin layers cure faster and more evenly.

2. What can I use instead of a UV light for resin?

Sunlight, nail lamps, or UV flashlights work best; regular household lights are usually ineffective.

3. Can UV resin be cured by sunlight?

Yes, bright, direct sunlight can harden resin, though thicker layers take longer.

4. How long does it take for UV resin to cure without a UV lamp?

Thin layers may cure in a few hours; thicker pours can take a full day or more.

5. Why is my resin sticky after sunlight curing?

Oxygen in the air can prevent the surface from fully hardening, especially in thin layers.

6. Are alternative curing methods safe?

Yes, but wear gloves, avoid eye exposure, and keep resin away from dust.

7. Who should try curing resin without a UV light?

Beginners or hobbyists working on small projects; large or professional piece