1 Introduction

The best epoxy resin for tables can transform a simple piece of wood into a stunning, durable, and glass-like masterpiece. Whether you’re creating a river table, live-edge design, or a custom dining surface, choosing the right resin is essential for clarity, durability, and ease of application. In this guide, we’ll break down everything you need to know from curing time and heat resistance to finish quality and special features—so you can select the perfect epoxy for your tabletop project.

Table of Contents

2. Curing Time & Working Time

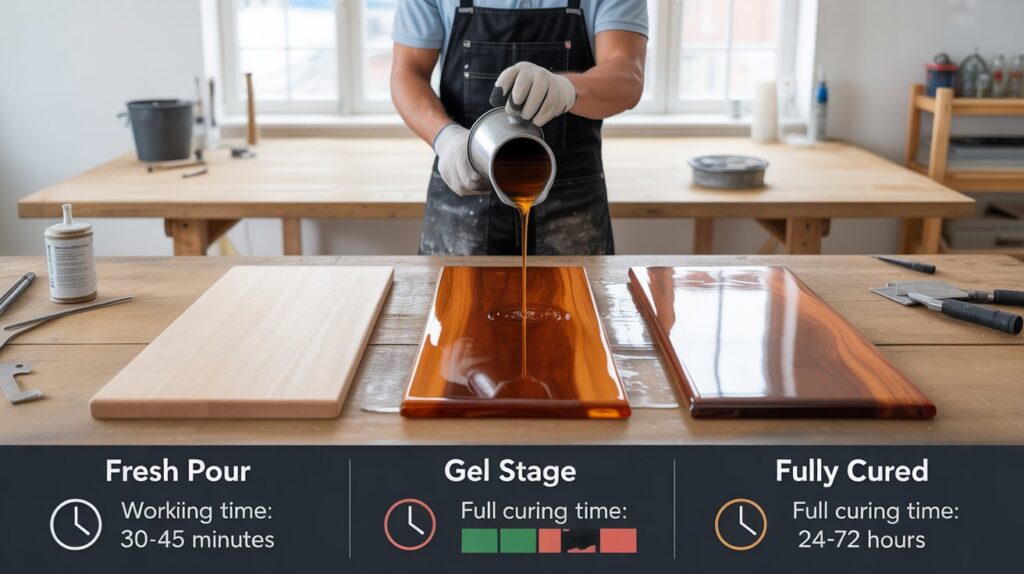

When choosing the best epoxy resin for tables, understanding the curing time and working time is essential for getting a smooth, bubble-free finish. Working time (also called pot life) refers to how long you can mix, pour, and spread the resin before it begins to thicken. A longer working time usually 30 to 60 minutes gives you more control during large pours, river tables, or detailed designs.

Curing time is how long the resin takes to harden completely. Most tabletop epoxies cure within 24–48 hours, while deep-pour formulas may take longer. Faster-curing resins are convenient, but they can create more bubbles and heat during the chemical reaction. Slower-curing resins often give better clarity and fewer surface imperfections, making them a preferred choice for thick table pours.

When comparing brands, look for resins that clearly list their working time and full cure time. This helps you choose the right product for your project size and skill level. Beginners typically benefit from resins with a slower cure and longer workability.

3. Durability & Hardness (Shore D Rating)

Durability is one of the most important factors when choosing the best epoxy resin for tables, especially for furniture that will be used daily. A durable resin should resist scratches, heat, impact, and surface dents. To measure this strength, manufacturers use the Shore D rating, which indicates how hard the resin becomes after curing.

Most high-quality table resins fall between Shore D 70 and 85. A higher rating means a tougher surface that withstands heavy use, making it ideal for dining tables, coffee tables, river tables, and bar tops. When the resin cures properly, it creates a solid protective layer that maintains a glossy finish without easily getting chipped or damaged.

A durable resin also helps prevent long-term issues like cracking, cloudiness, or imprints left by hot objects. If you expect your table to face frequent use, or if you’re building large furniture pieces, always choose a resin with a stronger hardness level.

4. Clarity & UV Resistance

Clarity is a key factor when selecting the best epoxy resin for tables, especially if you are creating river tables, live-edge designs, or projects where the wood grain needs to shine through. High-quality epoxy should cure crystal clear without cloudiness, streaks, or unwanted colour tones. A clear finish enhances the natural beauty of the wood and gives your table that smooth, glass-like appearance people expect from premium resin work.

Equally important is UV resistance. Over time, sunlight can cause epoxy to yellow, fade, or lose its glossy finish. The best table resins include UV stabilisers and anti-yellowing agents that protect the surface from discoloration. This is essential for tables, coffee tables, or any furniture placed near windows or exposed to daylight.

When comparing products, look for terms like “anti-yellowing formula,” “UV resistant,” or “non-yellowing technology.” These features ensure your table remains clear, glossy, and visually appealing for many years.

5. Pour Depth Capability

Pour depth is one of the most important features to consider when choosing the best epoxy resin for tables, especially for river tables and thick slab designs. Pour depth refers to how much resin you can pour in a single layer without overheating or causing surface defects. Different epoxies are designed for different depths, so choosing the right one ensures a smooth, bubble-free, and crack-free finish.

Tabletop epoxies typically allow shallow pours of 1/8 to 1/4 inch, which is perfect for surface coatings. However, deep pour resins are engineered for larger projects and can handle 1-inch, 2-inch, or even thicker single pours without overheating. These formulas cure more slowly, allowing bubbles to rise and escape while keeping the resin crystal clear.

When comparing products, always check the manufacturer’s recommended pour depth. Using the wrong type of resin can cause yellowing, cracking, or incomplete curing. For river tables and thick pours, choosing a deep-pour epoxy is essential for achieving professional results.

6. Heat Resistance After Curing

Heat resistance is a major factor when selecting the best epoxy resin for tables, especially for furniture that will be used daily. Once epoxy is fully cured, it should be able to handle moderate heat without becoming soft, leaving marks, or developing cloudy spots. High-quality table resins typically withstand temperatures between 120°C and 150°C (248°F–302°F), making them suitable for everyday use.

A resin with strong heat resistance protects the table surface from warm mugs, hot plates, and sunlight exposure. If the resin isn’t heat-resistant enough, the surface may warp, dent, or lose its shine over time. This is especially important for dining tables, kitchen islands, and coffee tables where heat contact is common.

When comparing epoxy brands, look for products that clearly list their heat tolerance or mention “high heat resistance” or “heat-stable formula.” These resins maintain their hardness, clarity, and glossy appearance even in warmer environments. Choosing a heat-stable epoxy ensures your table stays beautiful and durable for years.

7. Compatibility With Wood Types

When choosing the best epoxy resin for tables, it’s important to understand how well the resin works with different wood types. Every type of wood absorbs resin differently, so choosing a compatible formula helps prevent issues like bubbles, uneven curing, or poor adhesion.

Softwoods such as pine and cedar tend to absorb more resin, which can cause small air pockets to rise during curing. A resin with good bubble-release performance is ideal for these woods. Hardwoods like walnut, oak, and maple pair well with most tabletop epoxies because they absorb less resin and allow for a cleaner, smoother finish.

Some woods like teak, rosewood, and other oily species naturally contain oils that may interfere with resin bonding. In these cases, choosing a resin specifically designed for difficult woods or prepping the surface with a proper seal coat helps ensure strong adhesion.

If you’re working with live-edge slabs, a resin with strong sealing and self-leveling properties is recommended to fill cracks, voids, and natural imperfections. Checking the manufacturer’s details for wood compatibility can save you time and prevent curing problems.

8. Bubble Release Efficiency

Bubble release efficiency is a critical factor when selecting the best epoxy resin for tables. During mixing and pouring, air can get trapped in the resin, forming bubbles that may rise to the surface. If these bubbles aren’t released effectively, they can ruin the smooth, glass-like finish that makes epoxy tables so appealing.

High-quality table resins are formulated to minimize bubble formation and allow existing bubbles to rise and pop naturally. Some resins are also compatible with heat guns or torches, which help remove bubbles quickly and efficiently. Choosing a resin with excellent bubble-release properties reduces the need for constant touch-ups and ensures a flawless finish, especially for large or deep pours.

For beginners, using a resin that self-levels and naturally releases bubbles makes the process easier and produces professional-looking results. Always check product reviews and manufacturer instructions for tips on achieving optimal bubble release.

9. Mix Ratio & Ease of Application

When selecting the best epoxy resin for tables, the mix ratio and ease of application are crucial factors for achieving a smooth, durable finish. Most tabletop epoxies come in two-part formulas consisting of resin and hardener. The mix ratio commonly 1:1 or 2:1 determines how much of each component you need for proper curing. Following the correct ratio ensures the resin cures fully, avoids sticky or soft spots, and maintains its clarity and hardness.

Ease of application is another important consideration, especially for beginners. Low-viscosity, self-leveling resins are easier to pour, spread, and manipulate on the table surface. Some resins include user-friendly features like pre-measured components, which reduce the risk of errors during mixing. A resin that is easy to work with saves time and minimizes mistakes, helping you achieve a flawless tabletop finish.

Always mix thoroughly but gently to prevent introducing extra air bubbles. Proper mixing combined with the correct ratio ensures consistent curing, excellent adhesion, and long-lasting durability for your epoxy table project.

10. Food-Safe Certification After Curing

When selecting the best epoxy resin for tables, food safety is an essential consideration, especially for dining tables, countertops, and serving surfaces. Some epoxy resins are certified food-safe once fully cured, meaning they meet FDA standards and do not release harmful chemicals during contact with food or beverages.

Food-safe epoxy provides peace of mind for projects where your table will be used for meals or drinks. It ensures that hot dishes, utensils, or spilled liquids will not contaminate the surface or leach chemicals. While most high-quality tabletop resins are non-toxic after curing, it’s important to verify the product specifications and confirm the resin has passed food-safety tests.

Choosing a food-safe epoxy also protects the durability and longevity of your table. Certified resins are formulated to resist yellowing, staining, and degradation from liquids, making them ideal for both functional and decorative furniture pieces.

11. Finish Quality Gloss, Glass-like Look

One of the most sought-after features when choosing the best epoxy resin for tables is the finish quality. A high-quality resin should create a glossy, glass-like surface that enhances the natural beauty of the wood and highlights any decorative elements, such as river or live-edge designs.

The finish depends on factors like clarity, viscosity, and proper curing. A smooth, bubble-free pour combined with the right resin formula ensures a reflective, mirror-like surface that resists scratches and stains. High-gloss resins maintain their shine over time, while lower-quality resins can appear dull or develop haze, reducing the table’s aesthetic appeal.

For large surfaces or deep-pour projects, using a self-leveling epoxy with excellent clarity guarantees an even finish without uneven spots or streaks. Proper sanding and polishing after curing can further enhance the glass-like look, giving your table a professional, high-end appearance.

12. Odor Levels & Low-VOC Safety

When selecting the best epoxy resin for tables, odor levels and VOC (volatile organic compounds) content are important factors, especially if you are working indoors. Some epoxy resins release strong chemical smells during mixing and curing, which can be unpleasant or even hazardous in poorly ventilated spaces.

Low-VOC or odorless resins provide a safer and more comfortable working environment. They reduce fumes without compromising clarity, hardness, or durability, making them ideal for homes, workshops, or indoor projects. Using low-odor epoxy also minimizes the risk of headaches, nausea, or respiratory irritation during extended pours.

High-quality table resins often combine low-VOC formulations with user-friendly mixing ratios and self-leveling properties, making them easier to work with while keeping the workspace safe. For those sensitive to fumes, choosing a low-odor, non-toxic epoxy ensures both a beautiful table and a healthier crafting experience.

13. Price, Kit Size & Value for Money

When searching for the best epoxy resin for tables, price and kit size are important considerations, especially for large projects. Epoxy resin costs can vary widely depending on quality, brand, and included accessories. While cheaper resins may save money upfront, they can compromise clarity, durability, or ease of application. Investing in a high-quality resin often provides better long-term results and reduces the risk of mistakes.

Kit size also matters, as larger tables require more resin to achieve complete coverage. Many brands offer pre-measured kits with resin and hardener, which ensure accurate mixing and minimize waste. Some kits include extras like mixing tools, measuring cups, and spreaders, adding convenience and value for beginners and professionals alike.

When evaluating value for money, consider the resin’s durability, clarity, heat resistance, and ease of use in addition to the cost. Choosing a reliable, well-reviewed resin ensures you get a professional, long-lasting finish without unexpected problems or additional expenses.

14. Brand Reliability & Customer Support

Choosing a trusted brand is essential when searching for the best epoxy resin for tables. A reliable brand consistently delivers high-quality resin that cures properly, maintains clarity, and provides long-lasting durability. Reputable brands also follow strict quality control, ensuring each batch meets performance standards for viscosity, heat resistance, and scratch protection.

Customer support is equally important, especially for beginners or large projects. Brands that offer responsive support can answer technical questions, provide troubleshooting tips, and guide users on proper mixing, pouring, and curing techniques. Warranties or satisfaction guarantees are also valuable, giving you confidence in your purchase and reducing the risk of wasted materials.

When comparing products, check reviews, testimonials, and company reputation. Choosing a brand known for reliability and excellent customer support ensures your tabletop projects are successful and your investment in the best epoxy resin for tables is well-protected.

15. Special Features

When selecting the best epoxy resin for tables, it’s worth considering any special features that can enhance your project or make application easier. Some resins come with anti-yellowing technology, which keeps your table looking clear and bright over time, even when exposed to sunlight. Others are compatible with pigments, dyes, and metallic powders, allowing you to create unique designs, river tables, or artistic effects.

Certain resins offer heat resistance, UV stability, or deep-pour capability as additional benefits, making them ideal for thicker river tables or high-use surfaces. There are also beginner-friendly formulas that include pre-measured kits, low odor, or low-VOC composition, reducing the risk of errors and creating a safer working environment.

By paying attention to these special features, you can choose a resin that not only performs well but also meets the creative and practical demands of your project. Selecting the best epoxy resin for tables with these enhancements ensures a flawless finish and long-lasting durability.

Conclusion

Choosing the best epoxy resin for tables is essential for creating a durable, beautiful, and professional-looking surface. From viscosity and self-leveling performance to clarity, heat resistance, and special features, every factor plays a role in ensuring your table not only looks stunning but also stands the test of time.

By understanding key aspects like curing time, bubble release efficiency, compatibility with different wood types, and food-safe certification, you can select a resin that fits your project’s specific needs. Investing in a high-quality epoxy with excellent finish quality, low odor, and reliable brand support guarantees a smooth application process and long-lasting results.

Whether you’re making a river table, a live-edge dining table, or a decorative coffee table, the right epoxy resin will elevate your work and protect your investment for years to come. Take the time to compare products carefully, and you’ll achieve a flawless, glass-like finish that showcases your craftsmanship.

FAQs

1. What is the best epoxy resin for tables?

The best epoxy resin for tables is one that offers clarity, durability, self-leveling properties, and heat and UV resistance. Look for resins with low odor, food-safe certification, and compatibility with different wood types.

2. How long does epoxy resin take to cure on a table?

Curing time varies by product and pour depth. Most tabletop epoxies cure within 24–48 hours, while deep-pour resins may take several days to fully harden.“For optimal results, be sure to carefully follow the instructions provided by the manufacturer.”

3. Can I put hot items on an epoxy table?

High-quality epoxy resin can withstand moderate heat, usually up to 120–150°C (248–302°F). Using trivets or coasters is recommended to prevent surface marks and maintain durability.

4. Is epoxy resin safe for food surfaces?

Yes, many resins are certified food-safe after curing, meeting FDA standards. This makes them suitable for dining tables, countertops, and serving surfaces. Always confirm the product’s certification before use.

5. How do I prevent bubbles in my epoxy resin table?

Choose a resin with good bubble-release efficiency, pour slowly, and use a heat gun or torch to remove bubbles. Low-viscosity, self-leveling resins also minimize bubble formation.

6. Can I use colored or metallic pigments in table epoxy resin?

Yes, many resins are compatible with pigments, dyes, and metallic powders, allowing you to create river tables or custom designs. Always follow the resin manufacturer’s guidelines for best results.

7. How much epoxy resin do I need for my table?

The amount depends on the table’s size and desired pour thickness. Measure your table’s surface area and multiply by the pour depth to estimate the required volume. Pre-measured kits can simplify this process