1. Introduction

UV resin is a photopolymer resin that remains in liquid form until it is exposed to ultraviolet light. Many beginners ask what is UV resin made of because its ingredients are what allow it to cure quickly without mixing separate components. This unique formulation is why it is commonly used as a liquid resin that hardens under UV light for crafts, jewelry, and surface coatings.

Knowing what is UV resin made of helps explain how the resin curing process works and why ultraviolet light is required for hardening. As an ultraviolet light curing resin, UV resin reacts to light rather than air or time, which gives users more control during application. Understanding its composition also makes it easier to select the right product, achieve better clarity, and use the material more safely and effectively.

Table of Contents

2. What Is UV Resin Made Of? (Core Components Explained)

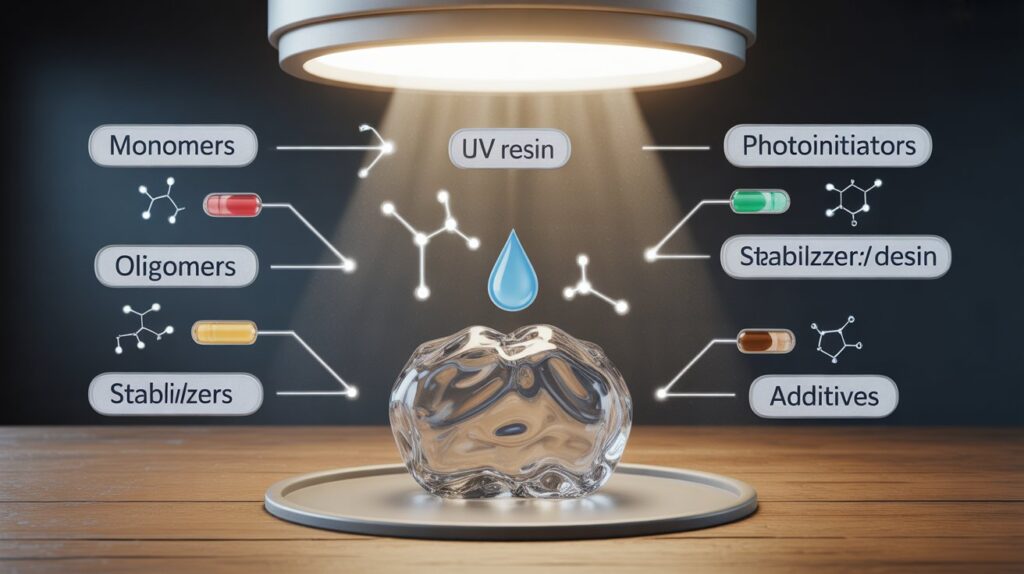

UV resin is a photopolymer resin made from a carefully balanced mix of materials that react when exposed to ultraviolet light. Each component plays a specific role in how the resin cures, how strong it becomes, and how clear the final result looks.

The base of UV resin consists of monomers and oligomers in resin, which form the structure once the material hardens. These substances determine flexibility, hardness, and surface finish. When UV light is applied, photoinitiators in UV resin absorb the light energy and trigger the chemical reaction that turns the liquid into a solid.

To improve performance, manufacturers also add small amounts of stabilizers and modifiers. These ingredients help control the resin curing process, prevent yellowing, and enhance durability. Together, these core components allow UV resin to cure quickly, stay transparent, and perform consistently under UV exposure.

3. What Are the Ingredients in UV Resin? (Detailed Breakdown)

UV resin is formulated from several key materials that work together to create a fast-curing and durable product. The primary ingredients include monomers and oligomers in resin, which form the main structure once the resin hardens. These ingredients control how rigid, flexible, or glossy the final surface becomes.

Another essential component is photoinitiators in UV resin. These substances react when exposed to ultraviolet light and start the hardening reaction. Without photoinitiators, the resin would remain liquid even under UV exposure.

UV resin also contains additives such as stabilizers, flow agents, and sometimes colorants. These materials improve shelf life, reduce yellowing, and ensure smooth application. Together, these ingredients allow UV resin to function as a reliable ultraviolet light curing resin with consistent curing and long-lasting results.

4. Monomers and Oligomers in Resin: The Building Blocks

Monomers and oligomers in resin are the core materials that give UV resin its structure and performance. Monomers are small molecules that help keep the resin fluid and easy to apply, while oligomers are larger molecules that provide strength, hardness, and surface durability.

During the resin curing process, these molecules link together when exposed to ultraviolet light, forming a solid and stable surface. The ratio between monomers and oligomers affects how flexible or rigid the cured resin becomes, as well as its clarity and scratch resistance.

By adjusting these building blocks, manufacturers can create UV resin formulas that cure faster, resist yellowing, and perform well in different applications such as coatings, molds, and fine-detail work.

5. Photoinitiators in UV Resin: How Curing Starts

Photoinitiators in UV resin are the key ingredients that start the hardening reaction. These compounds remain inactive while the resin is in liquid form and only react when exposed to ultraviolet light. Once activated, they release energy that triggers the bonding of surrounding resin materials.

This reaction is what allows UV resin to cure within minutes instead of hours. As part of an ultraviolet light curing resin system, photoinitiators control how fast the resin hardens and how evenly it cures across the surface.

The type and amount of photoinitiator used also affect clarity and finish. Proper formulation ensures a smooth cure, strong bonding, and consistent results during the resin curing process.

6. Additives and Stabilizers Used in UV Resin

UV resin often contains additives and stabilizers that improve performance, durability, and appearance. Stabilizers prevent yellowing and degradation over time, ensuring the cured resin remains clear and strong. Flow agents and thickeners help the liquid spread evenly, reducing bubbles and surface imperfections.

Other additives may include pigments, UV absorbers, or flexibilizers to enhance color, protect from sunlight, or adjust hardness. These components work alongside monomers and oligomers in resin and photoinitiators to ensure a smooth, reliable curing process. Proper formulation of additives and stabilizers is essential for consistent results in jewelry, coatings, and other UV-cured applications.

7. Is UV Resin a Chemical? Understanding the Science Simply

Yes, UV resin is a chemical, but it is a specially formulated photopolymer resin designed for safe use in crafting and small-scale applications. It contains monomers and oligomers in resin and photoinitiators, which react under ultraviolet light to harden the material.

Understanding its chemical nature helps explain why it behaves differently from regular liquids. The resin curing process is a controlled chemical reaction that transforms the liquid into a solid quickly. Knowing this also highlights the importance of handling uncured resin carefully, using gloves, and avoiding direct skin contact to prevent irritation.In simple terms, UV resin is a liquid resin that hardens under UV light because of its chemical composition, making it reliable and versatile for creative projects.

8. Liquid Resin That Hardens Under UV Light: How It Works

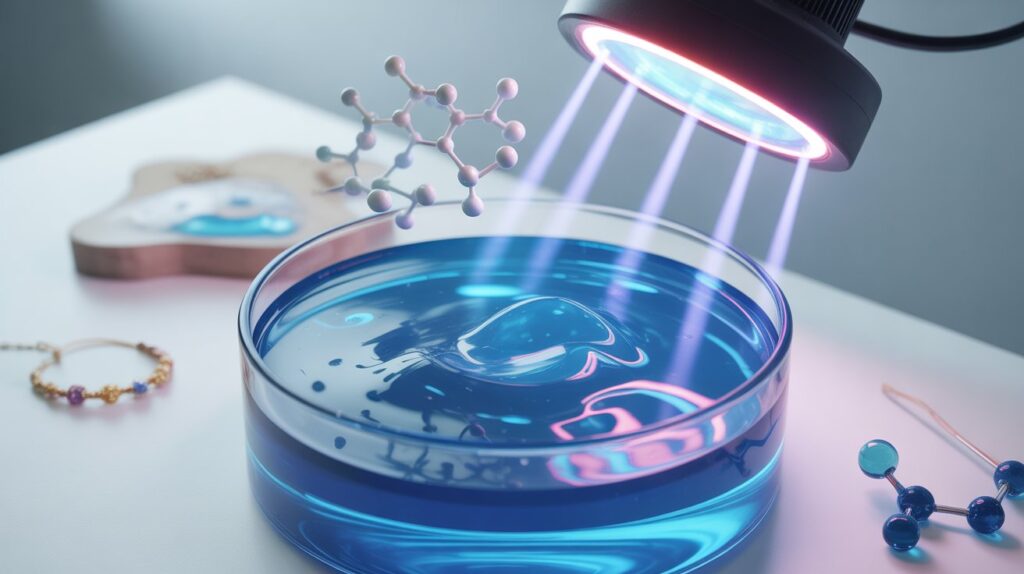

UV resin is a liquid resin that hardens under UV light due to a process called photopolymerization. When the liquid is exposed to ultraviolet light, photoinitiators in UV resin absorb the energy and trigger a chemical reaction. This reaction links the monomers and oligomers in resin together, forming a solid, durable surface.

The curing process is fast and precise, allowing the resin to harden only where the light reaches. This makes it ideal for detailed projects, coatings, and jewelry. The resin curing process is influenced by light intensity, resin thickness, and formulation, ensuring consistent results when used correctly.

9. Ultraviolet Light Curing Resin: The Resin Curing Process

The resin curing process for UV resin relies on ultraviolet light to trigger a rapid chemical reaction. When the liquid is exposed to UV light, photoinitiators in UV resin activate, causing the monomers and oligomers in resin to link together and form a solid structure.

This method allows precise control over where and how quickly the resin hardens, making it ideal for jewelry, coatings, and detailed craft projects. Factors such as light intensity, exposure time, and resin thickness affect the speed and quality of the cure. Proper application ensures a smooth, clear, and durable finish every time.

10. How UV Resin Composition Affects Strength and Clarity

The composition of UV resin directly impacts its strength, flexibility, and clarity. Monomers and oligomers in resin determine how hard or flexible the cured material will be, while the type and amount of photoinitiators in UV resin control how evenly and fully it hardens.

Additives and stabilizers also play a key role by preventing yellowing, improving durability, and maintaining transparency over time. A well-balanced formula ensures the resin cures smoothly, producing a clear, glossy finish that resists cracking or cloudiness. Understanding the composition helps users achieve professional-quality results consistently in jewelry, coatings, and decorative projects.

11. Safety and Chemical Considerations of UV Resin Ingredients

UV resin contains active chemicals, including monomers and oligomers in resin and photoinitiators in UV resin, which can irritate skin, eyes, or lungs if handled improperly. Always use gloves, work in a well-ventilated area, and avoid direct contact with uncured resin.

Some additives may release fumes during curing, so keeping UV light exposure controlled and wearing protective equipment is important. Understanding the chemical nature of the ingredients also helps prevent yellowing, uneven curing, or brittleness. Following safety guidelines ensures both effective resin curing process and long-term, safe use of UV resin in crafts and coatings.

12. FAQs

1. What is UV resin made from?

UV resin is a photopolymer resin made from monomers, oligomers, photoinitiators, and stabilizers. These components work together in the resin curing process to transform the liquid into a solid when exposed to ultraviolet light.

2. What chemicals are used in UV resin?

The main chemicals include monomers and oligomers, which form the structure, and photoinitiators, which start the hardening reaction. Additives and stabilizers are also included to improve clarity, durability, and prevent yellowing.

3. Is UV resin made of plastic?

Yes, UV resin behaves like a plastic once cured. It starts as a liquid resin that hardens under UV light but becomes solid, rigid, and durable after the resin curing process.

4. Does UV resin contain epoxy?

No, most UV resins do not contain epoxy. They are based on ultraviolet light curing resin chemistry, which is different from traditional two-part epoxy systems.

5. How does UV resin cure?

UV resin cures when ultraviolet light activates the photoinitiators in UV resin, triggering a chemical reaction that links the monomers and oligomers in resin, turning the liquid into a solid.

6. What makes UV resin harden?

Exposure to UV light is what makes UV resin harden. The light energy initiates the resin curing process, activating photoinitiators that convert the liquid into a solid surface quickly and evenly.

7. Is UV resin safe after curing?

Yes, UV resin is generally safe once fully cured. After hardening, it behaves like a solid photopolymer resin with minimal chemical activity, making it suitable for jewelry, coatings, and crafts.

13. Final Thoughts: Understanding What UV Resin Is Made Of

Understanding what UV resin is made of helps crafters and professionals know how it behaves during use. UV resin is a photopolymer resin composed of monomers, oligomers, photoinitiators, and additives that control flow, curing, and durability. The resin curing process relies on ultraviolet light to transform the liquid into a strong, clear, and long-lasting surface.

Knowing its composition allows users to choose the right product, achieve optimal clarity, and work safely. From improving flexibility to preventing yellowing, understanding what UV resin is made of ensures consistent, high-quality results in jewelry, coatings, and creative projects.