1. Introduction

If you’ve ever wondered how does UV resin work, the answer is simple: it’s a liquid that hardens when exposed to ultraviolet (UV) light. Unlike traditional resins that take hours to cure, UV resin reacts almost instantly under UV light, making it ideal for jewelry, crafts, and small DIY projects.

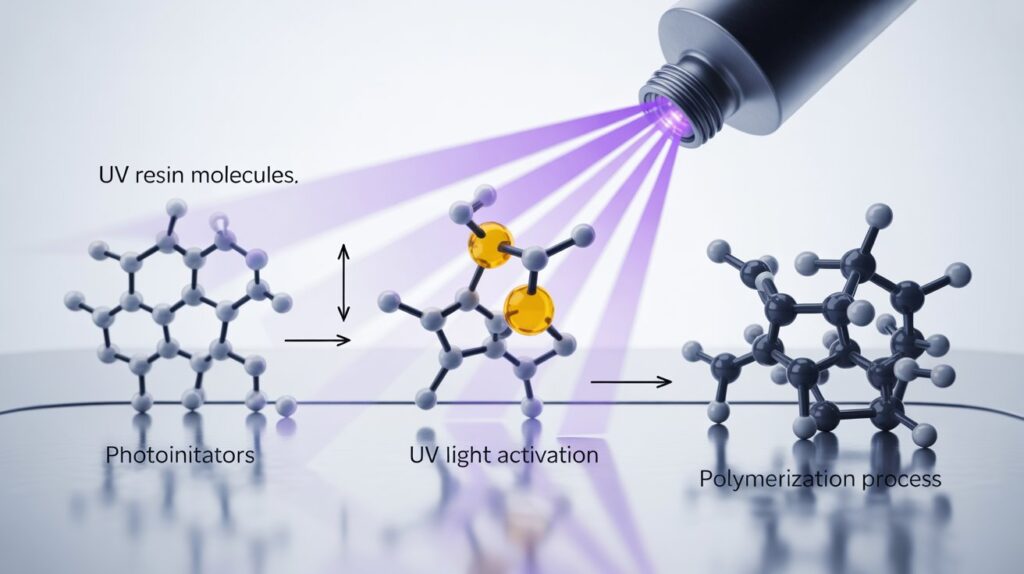

The secret lies in photoinitiators in the resin. When UV light hits these molecules, it triggers the UV resin curing process, turning the liquid into a solid. This explains how UV resin hardens so quickly compared to other types of resin.

UV resin curing time depends on the thickness of the layer and the strength of the UV light. Thin layers cure in seconds, while thicker pours may need multiple exposures. Knowing how does UV resin work helps you control the curing process and achieve smooth, solid results every time.

Table of Contents

2. What Is UV Resin? Understanding the Material

UV resin is a type of liquid resin that cures when exposed to ultraviolet (UV) light. It is commonly used in crafts, jewelry, nail art, and small DIY projects because it hardens quickly and produces a smooth, glossy finish. Unlike traditional epoxy resin, UV resin does not require mixing with a hardener or long curing times, making it ideal for beginners and fast projects.

The resin contains photoinitiators, special compounds that react to UV light and trigger the curing process. This reaction turns the liquid into a solid within minutes. UV resin is typically clear, allowing for easy embedding of small objects, pigments, or dyes.

It comes in different viscosity thin resins for detailed work and thicker resins for casting small molds. While it is fast-curing and convenient, proper UV light exposure is crucial to avoid sticky or uneven surfaces.

Overall, UV resin is valued for its speed, clarity, and versatility, making it a favorite material for precision crafting and small-scale projects.

3. How UV Resin Works: The Science Behind It

UV resin hardens through a process called photopolymerization, which is triggered by ultraviolet (UV) light. The resin contains special compounds called photo initiators. When exposed to UV light, these molecules absorb energy and start a chemical reaction that links resin molecules together, turning the liquid into a solid.

This reaction happens quickly, often in just a few seconds or minutes, depending on the resin layer thickness and the intensity of the UV light. Because the process only occurs under UV light, you have full control over when the resin sets, allowing time for precise shaping, embedding objects, or adding pigments.

The science behind this reaction also explains why proper UV light is crucial. Insufficient exposure can leave the surface sticky, while uneven light can create soft or under-cured areas. By understanding the curing process, you can achieve smooth, durable, and fully hardened results.

4. The UV Resin Curing Process Explained Step by Step

The curing of UV resin is a simple but precise process. Following these steps ensures a smooth, fully hardened finish:

Step 1: Prepare Your Workspace

Work in a clean, dust-free area. Ensure you have the UV light source ready and any molds, tools, or objects you want to embed nearby.

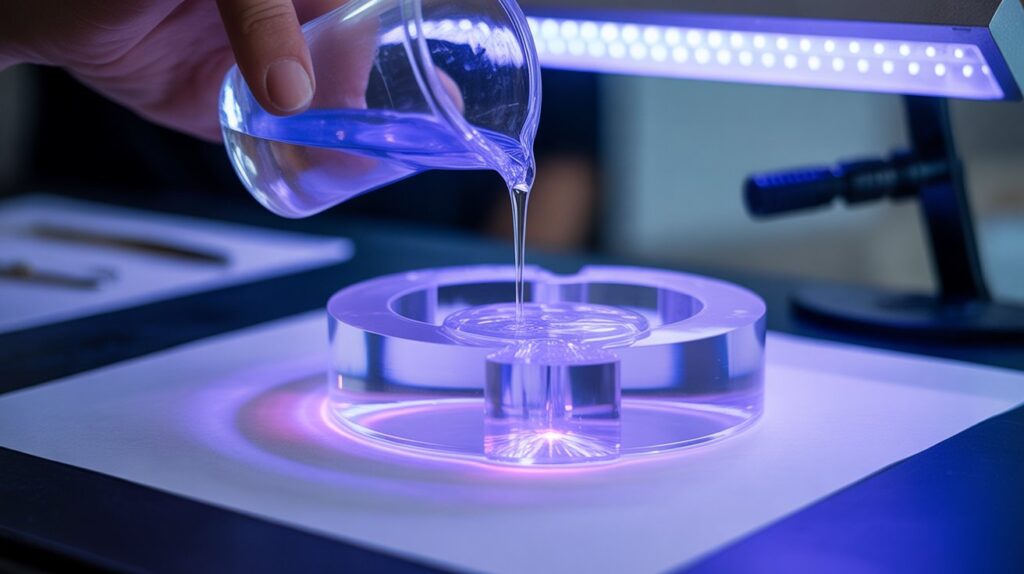

Step 2: Pour or Apply the Resin

Pour the resin carefully into your mold or onto your project surface. Use thin layers for faster curing and better clarity. Thicker layers may require multiple exposures.

Step 3: Position Under UV Light

Place the resin directly under a UV lamp or sunlight. Ensure the light covers the entire surface evenly to avoid soft spots.

Step 4: Monitor the Curing Time

Thin layers typically cure within seconds to a few minutes. Check for tackiness and repeat exposure if needed. Avoid touching the resin during this process.

Step 5: Post-Curing (Optional)

For added durability, some projects benefit from a brief additional exposure to UV light, especially for thicker pours.By following these steps, the resin undergoes a controlled UV resin curing process, hardening into a solid, glossy finish while maintaining precision and clarity.

5. How Long Does UV Resin Take to Cure?

The curing time of UV resin depends on several factors, including layer thickness, UV light intensity, and resin type. Thin layers, around 1–2 mm, can fully harden in 30 seconds to 2 minutes under a strong UV lamp. Thicker layers or deep pours may take 5–10 minutes or more, and sometimes require multiple exposures to ensure complete curing.

Sunlight can also cure UV resin, but it is less consistent. Direct sunlight may take longer due to varying intensity and angle. For best results, use a UV lamp with the recommended wavelength, usually 365–405 nm, and ensure even coverage.

Other factors affecting curing time include temperature and clarity. Cool or shaded environments can slow the reaction, while tinted or heavily pigmented resin may require longer exposure. Monitoring the surface for tackiness helps determine if additional curing is needed.

By understanding UV resin curing time, you can plan your projects efficiently and achieve smooth, fully hardened results every time.

6. Factors That Affect UV Resin Curing Time

Several factors influence how quickly UV resin hardens, and understanding them helps achieve a smooth, fully cured finish.

1. Layer Thickness

Thin layers cure faster, while thick pours require longer exposure or multiple sessions. Overly thick layers may remain sticky if not properly cured.

2. UV Light Strength and Wavelength

Stronger UV lamps with the correct wavelength (typically 365–405 nm) accelerate the curing process. Weak or uneven light can result in soft or under-cured areas.

3. Resin Type and Formulation

Different brands and formulations cure at slightly different rates. Some fast-cure resins harden in seconds, while others take several minutes for full strength.

4. Temperature and Environment

Cool temperatures can slow the reaction, and indirect or shaded light reduces effectiveness. A stable, well-lit workspace ensures consistent results.

5. Pigments and Additives

Opaque pigments, dyes, or embedded objects can block UV light and extend curing time. Transparent or lightly tinted resin cures faster.

By controlling these factors, you can reduce errors and achieve consistent results, ensuring the resin sets properly and maintains a smooth, durable finish.

7. What Type of UV Light Is Best for UV Resin?

Selecting the right UV light is key to curing resin evenly and efficiently. The most popular options are UV LED lamps and traditional UV lamps, each suited for different projects.

UV LED Lamps

These lamps are highly energy-efficient, produce minimal heat, and cure resin quickly. They work best for small-scale projects such as jewelry or nail designs. Most operate at wavelengths between 365–405 nm, which aligns with the photoinitiators in resin for optimal results.

Traditional UV Lamps

These lamps emit a broader range of UV light, making them suitable for larger pours. They are less energy-efficient and can generate more heat, which may affect delicate or detailed work.

Sunlight

Natural sunlight can also harden resin, but it is less predictable. Factors like the sun’s angle, weather, and intensity affect curing time. Direct sunlight is most effective but may require longer exposure compared to a UV lamp.

For reliable results, a UV LED lamp with the correct wavelength is recommended. It provides even curing, reduces soft spots, and ensures faster, more consistent results.

8. Common Mistakes That Prevent UV Resin from Curing Properly

Even with UV resin, certain mistakes can prevent it from fully hardening. Knowing these pitfalls helps ensure smooth, solid results.

1. Applying Layers Too Thick

Thick pours block UV light from reaching the lower layers, leaving the resin soft or tacky. Work in thin layers for best results.

2. Using Insufficient UV Light

Weak lamps or uneven light coverage can result in under-cured areas. Always use a lamp with the proper wavelength and ensure the light reaches all surfaces.

3. Skipping Exposure Time

Removing resin from the light source too soon prevents complete hardening. Follow the recommended exposure time and repeat if necessary.

4. Incorrect Light Distance

Placing the resin too far from the UV source reduces curing efficiency. Keep the resin at the recommended distance for consistent results.

5. Ignoring Resin Additives

Pigments, dyes, or embedded objects can block UV light and slow curing. Adjust exposure time or use thinner layers to compensate.

By avoiding these mistakes, you can achieve fully hardened, glossy resin that is free of sticky spots and imperfections. Proper technique and attention to curing details make a significant difference in project quality.

9. UV Resin vs Epoxy Resin: How Their Curing Works Differently

UV resin and epoxy resin are both popular for crafts, but their curing methods differ significantly.

UV Resin

UV resin hardens when exposed to ultraviolet light. This process is fast, often taking seconds to minutes for thin layers. It allows precise control over when the resin sets, making it ideal for small projects, detailed designs, and jewelry.

Epoxy Resin

Epoxy resin cures through a chemical reaction between resin and hardener. This process can take several hours to days, depending on the formulation and layer thickness. While epoxy is slower, it is better suited for larger projects or deep pours because it builds strength gradually.

Key Differences

- Speed: UV resin sets almost instantly, while epoxy takes hours.

- Control: UV resin allows precise placement before curing; epoxy begins hardening once mixed.

- Layering: UV resin works best in thin layers, whereas epoxy can handle thick pours.

- Equipment: UV resin requires a UV light source; epoxy does not.

Understanding these differences helps choose the right resin for your project, ensuring both efficiency and quality results.

10. Is UV Resin Fully Cured After UV Light?

While UV resin hardens quickly under UV light, it may not always be fully cured immediately. Thin layers often harden completely in seconds, but thicker pours or areas blocked by pigments or objects can remain slightly soft or tacky.

Factors Affecting Full Cure

- Layer Thickness: Thicker layers take longer and may require multiple exposures.

- UV Light Strength: Weak or uneven light can leave spots under-cured.

- Pigments and Additives: Opaque pigments or embedded items can block UV light, slowing the curing process.

Tips for Complete Curing

- Expose the resin to UV light from multiple angles to cover all surfaces.

- Allow extra time for thicker layers or heavily pigmented projects.

- Optional post-curing with additional UV exposure ensures maximum hardness.

By monitoring the surface and applying sufficient light, you can achieve a smooth, fully hardened finish suitable for crafting, jewelry, or other small projects.

11. Safety Tips When Working with UV Resin

UV resin is safe to use when proper precautions are followed. Handling it correctly ensures both health and project quality.

1. Wear Protective Gear

Always use nitrile gloves to avoid skin contact and safety glasses to protect your eyes from UV light.

2. Ensure Proper Ventilation

Work in a well-ventilated area. Some resins can release fumes, so open windows or use a fan to circulate air.

3. Avoid Direct Skin Exposure to UV Light

UV lamps can harm skin and eyes. Never look directly at the light and avoid exposing bare skin.

4. Keep Workspace Clean

Dust, dirt, or debris can stick to resin and affect curing. Cover your workspace and clean surfaces before starting.

5. Store Resin Safely

Keep resin containers sealed and away from heat or sunlight. Store out of reach of children and pets.

Following these tips ensures a safe crafting experience and helps produce smooth, fully cured resin projects without health risks.

FAQs

1. How does UV resin cure?

UV resin cures through a chemical reaction triggered by ultraviolet (UV) light. The photoinitiators in the resin activate under UV light, turning the liquid into a solid quickly.

2. What makes UV resin harden?

UV light activates special compounds called photoinitiators inside the resin. This starts a chain reaction that links molecules together, causing the resin to harden.

3. Does UV resin need UV light to cure?

Yes. UV light is required to trigger the curing process. Without it, the resin will remain soft or sticky.

4. Can UV resin cure in sunlight?

Yes, sunlight can cure UV resin, but it is less consistent. The curing time depends on the sun’s intensity, angle, and weather conditions.

5. How long does UV resin take to cure?

Thin layers can cure in 30 seconds to a few minutes under a strong UV lamp. Thicker layers may take 5–10 minutes or more and sometimes require multiple exposures.

6. Why is my UV resin not curing?

Common reasons include thick layers, weak or uneven UV light, insufficient exposure time, or pigments/objects blocking the light. Correcting these issues usually resolves the problem.

7. Does UV resin cure without a lamp?

It can cure in direct sunlight, but a UV lamp is more reliable and faster. Indoors or in shaded areas, the resin will not fully harden without a proper UV light source.

8. Can I layer UV resin without it sticking?

Yes. You can apply multiple layers, but each layer must be fully cured before adding the next. Thin layers cure faster and reduce the risk of sticky spots.

9. Does adding pigments or objects affect curing time?

Yes. Opaque pigments, dyes, or embedded items can block UV light, slowing the curing process. Use thinner layers or increase UV exposure to ensure full hardening.

10. Is UV resin safe to use indoors?

Yes, if proper precautions are followed. Always work in a well-ventilated area, wear gloves, and avoid direct exposure to UV light to protect your skin and eyes.

12. Final Thoughts:

UV resin is a fast-curing, versatile material ideal for small-scale projects, jewelry, crafts, and repairs. Its ability to harden quickly under ultraviolet light allows for precise control, smooth finishes, and minimal waiting time compared to traditional resins.

While it is convenient and beginner-friendly, success depends on proper technique, including using the correct light source, applying thin layers, and monitoring curing time. Awareness of common mistakes and safety precautions ensures consistent, high-quality results.

For anyone looking to create detailed designs or small projects quickly, UV resin offers an efficient and reliable option. With proper handling and understanding of the curing process, it can produce beautiful, durable results every time.