1.Introduction

Choosing the right uv light for resin is essential for achieving flawless results in your jewellery, charms, or craft projects. With so many options available, it can be challenging to know which lamp offers the best curing speed, intensity, safety, and durability. This guide breaks down everything you need to know from wavelength and beam coverage to timers, ergonomics, and value so you can pick the perfect UV lamp that matches your crafting needs and brings your resin creations to life.

2 Why Wavelength Matters When Choosing a UV Light for Resin

When selecting a Uv light for resin, one of the most important factors to compare is the wavelength it emits. UV resin is formulated to cure under specific wavelengths, and using the correct range ensures faster, smoother, and stronger results.

Most UV lights for resin fall within two common wavelengths: 365nm and 395nm.

Here’s what each one means and why it matters:

365nm (Deep UV) This wavelength penetrates resin more effectively, providing a stronger and more complete cure especially for thicker or more detailed pieces. It’s ideal for jewelry, charms, and small casting projects where clarity and hardness matter.

395nm (Standard UV / Near UV) This wavelength is brighter to the eye and works well for thin layers, top coats, and smaller resin applications. It may cure slightly slower than 365nm but is still widely used in budget-friendly UV lamps.

Dual-Wavelength Lamps (365nm + 395nm) These provide the best coverage because they cure multiple resin types more efficiently. Dual-range lights are highly recommended for beginners and crafters who use different brands of UV resin.

Why the Right Wavelength Matters

Using the correct wavelength ensures:

Faster curing times

Stronger and more durable finished pieces

Reduced tackiness or under-cured surfaces

Better results with both clear and colored resins

If the wavelength doesn’t match the resin formulation, the resin may cure unevenly, remain sticky, or take much longer to harden.

3. Intensity Power (MW/cm² or W)

Why Light Strength Matters When Choosing a UV Light for Resin.

When comparing any uv light for resin, the intensity measured in MW/cm² (millilitres per square centimetre) or W (watts) is one of the biggest factors that affects how well your resin cures. Simply put, higher intensity means faster curing, better depth penetration, and stronger finished results.

Understanding UV Light Intensity

mW/cm² (Curing Strength)

This measurement tells you how much UV energy hits the surface of your resin. A higher number means the resin will cure quicker and more evenly.

Low intensity (0–10 mW/cm²): Slow curing, best for small items.

Medium intensity (10–20 mW/cm²): Ideal for most jewelry and craft projects.

High intensity (20+ mW/cm²): Fastest results, great for deeper or thicker resin pours.

Wattage (Lamp Power)

The watt rating (like 6W, 24W, 48W) reflects the lamp’s total power. While wattage alone doesn’t guarantee performance, higher watt lamps usually provide stronger, more consistent curing.

How Intensity Affects Curing Speed and Depth

A strong uv light for resin ensures:

Faster curing times

Better curing of slightly thicker layers

Reduced tacky surfaces

Less risk of bubbles or soft spots

If the intensity is too low, the resin may cure only on the surface, leaving the underside soft or sticky.

What kind of UV light do I need for resin?

You need a UV lamp with at least 10–20 mW/cm² intensity and 365–405nm wavelength for reliable curing of most crafting resins.

Can you cure resin with UV light?

Yes, you can cure resin with UV light as long as you use UV resin, which is designed to harden under UV exposure.

What can I use instead of a UV light for resin?

If you don’t have a UV lamp, you can use direct sunlight, but curing will be slower and less predictable.

How long does it take for epoxy resin to cure under UV light? Traditional epoxy resin cannot cure fully under UV light; only UV resin cures this way. UV resin usually hardens within 1–5 minutes, depending on light intensity.

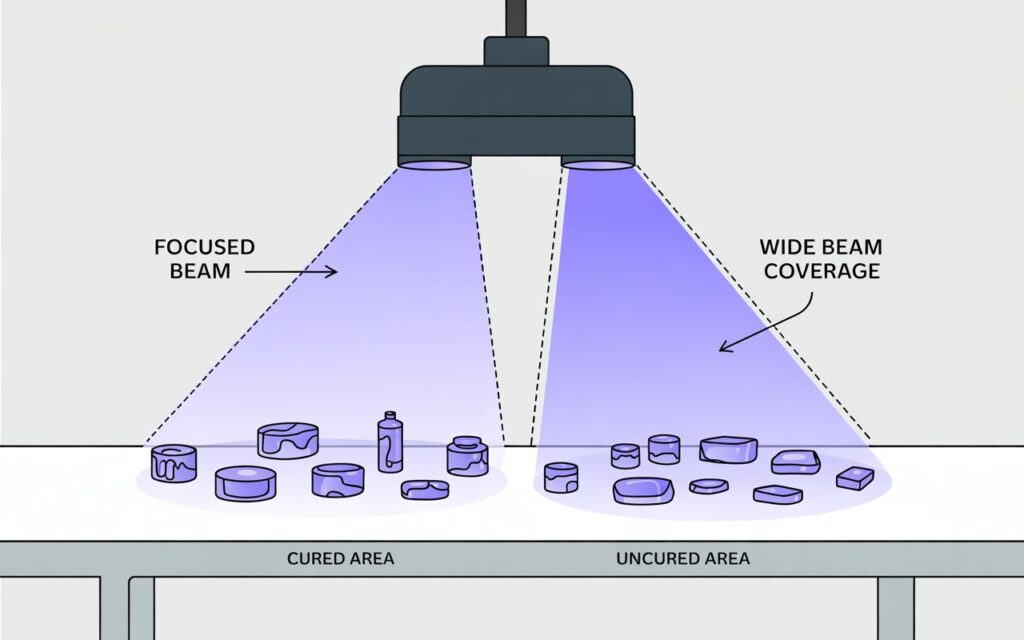

4. Why Coverage Matters When Choosing a UV Light for Resin

When selecting a uv light for resin, the curing area and beam shape play a major role in how evenly and efficiently your projects cure. A UV lamp with poor coverage can cause uneven hardening, tacky surfaces, or slow curing times.

What Is the Curing Area?

The curing area is the amount of space the UV light can cover at once.

A larger curing area is useful if you often work on:

Multiple small charms

Jewelry trays

Bigger molds

Several pieces that need curing together

A smaller curing area works fine when curing: Single pendants

Keychains

Mini craft items.

Understanding the curing area also helps answer what kind of UV light do I need for resin?

You should choose one that matches your project size to avoid curing your resin piece in multiple passes.

Why Beam Shape Matters

The beam shape shows how the UV light spreads across the surface:

Focused Beam

Strong in a small area, ideal for detailed or precise resin work.

Wide Beam. Covers more space, perfect for curing multiple resin pieces at the same time.

A good uv light for resin should deliver even beam distribution. Uneven beams may leave edges soft, requiring extra curing time and raising common questions like can you cure resin with UV light? Yes, but only if the beam covers your project properly.

Additional Helpful Notes

Some beginners ask what can I use instead of a UV light for resin?

You can use sunlight, but it won’t give you the same beam control or even coverage as a proper UV lamp. Also, remember that epoxy resin does not fully cure under UV light. So when people ask, how long does it take for epoxy resin to cure under UV light?. UV lamps are designed for UV resin only, which cures in 1–5 minutes, depending on beam strength and coverage.

5. Why Curing Time Matters When Choosing a UV Light for Resin

One of the most important factors to compare when selecting a uv light for resin is the curing time. Faster and more consistent curing helps you finish projects efficiently, avoid tacky spots, and achieve a strong, glass-like finish.

Performance tests usually measure how long it takes a UV lamp to fully cure a standard layer of UV resin. The results can vary based on light intensity, wavelength, beam coverage, and resin thickness.

Typical Curing Times Based on UV Light Strength

Low-Intensity UV Light: Takes 3–6 minutes for thin layers and even longer for thicker ones. Best for occasional use or small projects.

Medium-Intensity UV Light: Cures most UV resin pieces in 1–3 minutes, offering a good balance of speed and quality.

High-Intensity UV Light: Delivers the fastest performance, curing thin UV resin layers in 30–60 seconds and thicker pieces in under 2 minutes.

These performance tests help buyers understand how quickly their resin can harden under real conditions.

Factors That Affect Curing Time

Several elements influence how long your UV resin takes to cure:

Wavelength accuracy If the wavelength doesn’t match the resin formula, it may cure slower.

Beam shape and coverage Poor coverage can leave edges soft and require extra curing passes.

Resin thickness Thicker pours need more time or multiple curing rounds.

Light intensity Higher mW/cm² typically cures resin much faster.

What kind of UV light do I need for resin?

You need a lamp with the correct wavelength (365 405nm) and strong, even light output.

Can you cure resin with UV light?

Yes. UV resin is specifically designed to harden quickly when exposed to UV light, which is why curing time is one of the main comparisons between lamps.

What can I use instead of a UV light for resin?

You can use sunlight, but curing time becomes unpredictable and much slower compared to a controlled UV lamp.

How long does it take for epoxy resin to cure under UV light?

Epoxy resin does not cure properly under UV light, even with long exposure. Only UV resin cures quickly usually within 30 seconds to 5 minutes, depending on performance tests.

6. Understanding UV Lamp Technology for Better Resin Curing

When choosing a uv light for resin, the light type and technology used in the lamp plays a major role in curing speed, efficiency, and overall project quality. Different UV light technologies offer different strengths, so understanding how they work will help you pick the best option for your crafting needs.

1. LED UV Lights

LED UV lamps are the most popular choice for resin curing today because they are:

Fast and energy-efficient

Long-lasting (up to 50,000 hours)

Low heat, reducing the risk of yellowing

Available in multiple wavelengths, such as 365nm, 385nm, and 405nm

LED lights deliver strong, focused UV output, making them ideal for jewellery, small craft pieces, and quick curing sessions.

2. Fluorescent UV Lights

Traditional fluorescent UV lamps are less common but still used because they provide:

Broader light coverage

Lower upfront cost

Good curing for larger or multiple resin pieces

However

Produce more heat

Have shorter bulb life

Cure resin slower than LED lights

For most craters, LED technology is now the preferred choice.

3. Dual-Wavelength UV Lights

Dual-wavelength lamps combine two wavelengths—often 365nm + 405nm—to cure a wider range of UV resin formulas. This technology offers:

Consistent curing across resin brands

Faster hardening for thicker pours

Better penetration and surface clarity

If you work with different types of UV resin, dual-wavelength technology is a highly reliable option.

4. UV Nail Lamps For Resin Use

Many beginners wonder if UV nail lamps can cure resin.

Yes they can, as long as the wavelength matches the needs of UV resin. Nail lamps use similar LED technology, making them a budget-friendly alternative.

5. Why Light Technology Matters

The type of UV light you choose affects:

Curing speed

Project size compatibility

Resin hardness and gloss

Energy use and heat control

Choosing the right technology helps answer common questions like

what kind of UV light do I need for resin?

For most projects, an LED or dual-wavelength UV light provides the best results.

7. Why Custom Controls Matter When Choosing a UV Light for Resin

When selecting a UV light for resin, adjustable settings and built-in timers make curing easier, more precise, and much more consistent. These features help both beginners and experienced crafters avoid over-curing, under-curing, and heat buildup common issues when working with UV resin.

1. Timer Presets

Most modern UV lamps include preset timers such as 30 seconds, 60 seconds, 90 seconds, or 120 seconds.

These presets help you:

Cure different project sizes accurately

Avoid guessing curing times

Prevent overheating or yellowing

Keep curing consistent across multiple pieces

Using a preset timer also ensures the resin cures evenly, which is especially helpful when people wonder Can you cure resin with UV light properly?” Yes timers make it predictable and repeatable.

2. Adjustable Power Levels

Some UV lamps allow you to switch between low, medium, and high intensity modes. Adjustable power is useful for:

Thin coatings that need gentle curing

Thick pours that need stronger UV exposure

Preventing shrinkage or surface ripples

Reducing excess heat for delicate molds

This feature also helps answer “What kind of UV light do I need for resin?”

Ideally, one that lets you control intensity based on your project type.

3. Auto Shut-Off

Auto shut-off is a safety and convenience feature. The lamp automatically turns off once the timer ends, which helps:

Prevent over-curing

Reduce energy use

Add safety during long crafting sessions

It’s especially useful if you’re curing multiple pieces at once.

4. Memory Function

Some UV resin lamps remember your last-used timer and power settings. This is helpful for:

Repeating identical curing cycles

Speeding up batch production

Improving consistency

If you do a lot of jewellery making or repetitive projects, this feature saves time and effort.

5. Why These Features Matter

Adjustable settings and timers make curing more efficient, which helps avoid issues like tackiness or uneven hardening.

They’re also helpful if you ever wonder:

What can I use instead of a UV light for resin?

Sunlight works but it offers no control, unlike UV lamps with timers.

How long does it take for epoxy resin to cure under UV light?

Epoxy resin doesn’t cure under UV light, but UV resin cures within 30 seconds to a few minutes and timers help achieve perfect results.

8. Why Design and Size Matter When Choosing a UV Light for Resin

When selecting a UV light for resin, the lamp’s build quality, physical size, and portability play an important role in your crafting experience. A well-designed lamp ensures durability, ease of use, and convenient placement for curing resin pieces of different sizes.

1. Build Quality

A sturdy, high-quality UV lamp lasts longer and performs consistently. Look for lamps with:

Durable plastic or metal housing

Heat-resistant components

Stable base to prevent tipping

Quality LED or fluorescent bulbs

Strong construction reduces the risk of damage and ensures the lamp can handle frequent use.

2. Size Considerations

The lamp’s size determines how large a resin piece or batch of pieces you can cure at once.

Compact / Mini Lamps

Ideal for small jewelry pieces, keychains, and small charms. Great for desktops with limited space.

Medium Lamps

Can handle multiple resin pieces at once, making them suitable for hobbyists who craft larger items or small batches.

Large / Professional Lamps

Designed for bigger molds or commercial use, allowing simultaneous curing of multiple items.

Choosing the right size answers the question “What kind of UV light do I need for resin?” it depends on the types of projects you make most often.

3. Portability

Portability is especially important for crafters who:

Move their workspace frequently

Attend workshops or craft fairs

Want a lamp that can be stored easily

Portable UV lights are generally lightweight and often battery-powered or USB-compatible. While smaller lamps are easier to carry, larger lamps provide faster curing and larger coverage.

4. Why Build, Size & Portability Matter

The lamp’s design affects:

Curing efficiency

Comfort during use

Safety and durability

Flexibility in workspace setup

Selecting a lamp that fits your crafting needs helps ensure smooth, consistent curing of UV resin.

9. Why Resin Compatibility Matters When Choosing a UV Light for Resin

When selecting a UV light for resin, it’s crucial to consider which types of resin the lamp can effectively cure. Not all resins respond the same way to UV light, so using the right lamp ensures fast, even curing and a durable finished piece.

1. UV Resin

UV resin is specifically formulated to cure under UV light. It hardens quickly, often in 30 seconds to a few minutes, depending on intensity and layer thickness.

Works best with 365nm–405nm wavelengths

Can be cured in thin layers or molds

Ideal for jewelry, charms, and small decorative items

This is the type of resin most compatible with UV light for resin and answers the common question: Can you cure resin with UV light? yes, but only with UV resin, not standard epoxy.

2. Epoxy Resin

Traditional epoxy resin does not cure properly under UV light. It requires chemical hardeners for full curing.

UV light may only cure the top layer, leaving the underside soft

For epoxy projects, use sunlight for minimal effect or rely on the resin’s standard curing process

Helps explain the question: “How long does it take for epoxy resin to cure under UV light?” epoxy won’t fully cure under UV, unlike UV resin

3. Hybrid or Speciality Resins

Some specialty resins, like hybrid gel or nail resins, are formulated to cure under UV or LED lights:

These resins require matching wavelengths (often 365–405nm)

Dual-wavelength UV lamps work best to ensure full curing

Useful for crafters experimenting with multiple resin types

4. Why Compatibility Matters

Choosing a uv light for resin that matches your resin type ensures:

Faster and even curing

Reduced tackiness or incomplete hardening

Better clarity, hardness, and durability

What kind of UV light do I need for resin? A lamp compatible with your resin type and project size is essential.

10. Why Safety Matters When Choosing a UV Light for Resin

When selecting a uv light for resin, safety features are just as important as curing performance. UV light can be harmful to your eyes and skin if used incorrectly, so a lamp with built-in safety measures ensures you can craft confidently and avoid accidents.

1. Protective Shields and Covers

Many UV lamps come with a protective cover or shield to block direct UV exposure. Benefits include:

Preventing eye damage

Reducing skin exposure to UV rays

Minimizing the risk of accidental overexposure

Even with shields, it’s recommended to wear UV-safe gloves or glasses when working with UV resin.

2. Auto Shut-Off Timer

A built-in timer automatically turns off the lamp after a set period. This prevents:

Over-curing your resin

Excessive heat buildup

Unnecessary energy use

Timers also make curing predictable

Can you cure resin with UV light?. yes, safely, if you use a lamp with timers.

3. Heat Control / Low-Heat Design

Some UV lamps generate less heat, which is especially important for delicate molds or resin types.

Prevents warping or discoloration of resin

Allows longer curing sessions without overheating

Improves consistency for multi-layer projects

4. Stable Base / Anti-Tip Design

A lamp with a solid base or anti-slip feet reduces the risk of tipping over mid-curing, which can ruin your resin project.

Helps beginners feel safer during use

Essential for small workspace or crowded craft areas

5. Why Safety Features Matter

Safety features protect both you and your resin projects, ensuring that UV curing is effective and worry-free.

What kind of UV light do I need for resin? One with shields, timers, and stable construction is ideal.

What can I use instead of a UV light for resin? While sunlight is an alternative, it offers no safety control and uneven curing. Choosing a lamp with robust safety features allows you to focus on crafting without risk.

11. Why Long-Lasting UV Lights Matter for Resin Crafters

When choosing a uv light for resin, it’s important to consider durability and maintenance. A lamp that lasts longer and requires minimal upkeep saves money, prevents interruptions in your projects, and ensures consistent results every time.

1. Lifespan of the Lamp

Modern UV lamps, especially LED UV lights, have a long lifespan often up to 50,000 hours. High-quality bulbs or LED’s ensure:

Consistent curing performance over time

Less frequent replacements

Reduced risk of uneven curing due to worn-out bulbs

Fluorescent UV lamps typically have a shorter lifespan and may need replacement more often.

2. Easy Maintenance

Maintenance for a UV lamp is generally simple:

Wipe the surface and LED bulbs with a soft, dry cloth to remove dust or resin spills

Avoid using water or harsh chemicals on electrical components

Check for loose parts or connections periodically

A well-maintained lamp reduces downtime and keeps curing results predictable, which is especially important for answering the LSI question: “Can you cure resin with UV light?” proper maintenance ensures reliable curing every time.

3. Replaceable Parts

Some lamps allow you to replace LEDs or bulbs, extending the lamp’s overall life. Features to look for:

Easily accessible bulbs or LED arrays

Compatibility with replacement parts from the manufacturer

Simple instructions for swapping components

4. Durable Build

Durability also depends on construction. Look for:

Heat-resistant housing

Stable bases

Scratch- and impact-resistant materials

Durable UV lamps handle frequent use, accidental bumps, and high heat without losing performance.

5. Why Durability & Maintenance Matter

Choosing a uv light for resin that is durable and easy to maintain ensures:

Reliable curing performance

Consistent results for jewelry, charms, and craft projects

Lower long-term costs

Peace of mind for beginners and professionals alike

12. Why Comfort and Usability Matter When Choosing a UV Light for Resin

When selecting a uv light for resin, ease of use and ergonomic design are crucial for a comfortable and efficient crafting experience. A lamp that is intuitive, lightweight, and user-friendly ensures consistent curing results without strain or frustration.

1. Simple Controls

Most modern UV lamps feature easy-to-understand buttons or touch panels for timers, power levels, and settings. Benefits include:

Quick setup for beginners

Consistent curing cycles without guesswork

Reduced mistakes like over-curing or uneven curing

Clear controls also make answering LSI keyword questions easier, such as “What kind of UV light do I need for resin?” a user-friendly lamp with simple controls is ideal for all skill levels.

2. Ergonomic Design

Ergonomics refers to how the lamp fits your workspace and hand movements:

Lightweight lamps are easy to move or adjust

Low-profile or compact designs allow working in small spaces

Tilted or adjustable lamps help focus light where it’s needed.

An ergonomic design reduces strain during long crafting sessions and improves precision, especially for intricate jewelry or resin pieces.

3. Visibility

Good visibility ensures that you can monitor your resin curing without awkward angles:

Transparent or open-top designs allow easy placement of molds

LED indicators show when the lamp is on and the timer status

Helps beginners track curing progress and avoid mistakes

4. Beginner-Friendly Features

Some lamps include memory settings, auto shut-off, or pre-set timers that make them beginner-friendly:

Prevents over-curing for those new to resin

Makes batch curing consistent

Enhances confidence and safety while using UV light

5. Why Ease of Use & Ergonomics Matter

Choosing a uv light for resin that is easy to operate and ergonomically designed ensures:

Comfortable crafting sessions

Predictable and consistent results

Reduced risk of mistakes or wasted resin

A better overall experience for both beginners and professionals.

Can you cure resin with UV light

yes, and it’s much easier when the lamp is designed for smooth, stress-free use.

13. Finding the Right Balance When Choosing a UV Light for Resin

When selecting a uv light for resin, considering both price and value is essential. While it’s tempting to choose the cheapest option, investing in a lamp with the right features, durability, and performance ensures consistent curing results and long-term satisfaction.

1. Budget UV Lamps

Budget lamps are usually smaller, with lower intensity and fewer features:

Pros: Affordable, lightweight, good for beginners or small projects

Cons: Slower curing times, smaller coverage, fewer safety features

These are a good starting point for hobbyists asking, “What kind of UV light do I need for resin?” just be aware of their limitations for larger or more detailed projects.

2. Mid-Range UV Lamps

Mid-range lamps typically offer better intensity, adjustable timers, and more ergonomic designs:

Pros: Faster curing, wider coverage, built-in safety features

Cons: Slightly higher upfront cost

These lamps provide a good price-to-value ratio, making them ideal for frequent crafters or those creating multiple pieces at once.

3. High-End / Professional UV Lamps

High-end lamps deliver maximum performance, dual-wavelength curing, and premium build quality:

Pros: Fastest curing, large coverage, long lifespan, excellent safety features

Cons: Expensive upfront investment

Professional lamps are a smart choice for serious crafters, small businesses, or anyone who wants reliable results every time. Can you cure resin with UV light? efficiently and safely for any project size.

4. Balancing Price and Value

When evaluating UV lamps, consider:

Features vs cost – timers, adjustable intensity, safety shields, and durability

Frequency of use – occasional vs frequent crafting

Project size – small jewelry pieces vs larger resin molds

Sometimes spending a little more upfront saves time, prevents mistakes, and ensures longer-lasting performance.

14. Why Reviews Matter When Choosing a UV Light for Resin

When selecting a uv light for resin, considering customer feedback and reliability is crucial. Reviews provide real-world insights into performance, durability, and ease of use information that specifications alone can’t fully convey. Understanding how a lamp performs in everyday use helps you make a smarter purchase.

1. Performance Reviews

Look for feedback on:

Curing speed – does the lamp cure resin evenly and quickly?

Beam coverage – are there any dark spots or uneven areas?

Consistency – does it perform well after multiple uses?

Can you cure resin with UV light? A reliable lamp will consistently cure UV resin properly every time.

2. Reliability and Build Quality

Feedback often highlights durability issues or praises well-built lamps. Check reviews for:

Bulb or LED lifespan

Stability and anti-tip design

Heat management

Long-term performance

A lamp with positive reviews for reliability ensures that your investment lasts, saving money and frustration over time.

3. Ease of Use Insights

Real users frequently comment on ergonomics, timers, and adjustable settings:

Are the controls intuitive?

Is the lamp comfortable to use for extended sessions?

Does it meet expectations for beginner-friendly operation?

What kind of UV light do I need for resin? one that is highly rated for ease of use will be better for both beginners and advanced crafters.

4. Price vs Satisfaction

Customer reviews can also indicate whether a UV lamp offers good value for the price. A mid-range lamp with excellent feedback may outperform a cheaper option, saving time and improving project quality.

5. Why Customer Feedback Matters

Avoid poorly performing lamps

Confirm that advertised features actually work

Understand real-world curing times

Make an informed decision that fits your resin projects.

Positive feedback combined with a reliable build is often the best indicator of a high-quality uv light for resin.

15. Conclusion

Selecting the right uv light for resin is essential for achieving professional-quality results in your resin projects. From wavelength and intensity to curing area, safety features, and ease of use, each factor contributes to how well your resin cures and how enjoyable the crafting process will be.

For beginners, a compact, user-friendly LED UV lamp with timers and safety shields offers reliable curing and ease of use. For advanced crafters or those working on larger projects, a mid-range or professional dual-wavelength lamp with adjustable settings provides faster curing, better coverage, and long-term durability.

Considering customer feedback and value for money ensures you invest in a lamp that is reliable, efficient, and suits your resin crafting needs. Choosing the right UV light eliminates common issues like tacky surfaces, uneven curing, or project failures, making your creative process smoother and more enjoyable.

FAQs

1. What kind of UV light do I need for resin?

For most resin projects, you need a UV lamp with a wavelength of 365–405nm and sufficient intensity (10–20 mW/cm²) to cure UV resin evenly. LED lamps are preferred for faster curing and energy efficiency.

2. Can you cure resin with UV light?

Yes, UV resin is specifically designed to cure under UV light. Traditional epoxy resin does not fully cure under UV light, so make sure you are using the correct resin type.

3. What can I use instead of a UV light for resin?

If you don’t have a UV lamp, sunlight can cure UV resin, but it is slower and less predictable. For precise and fast results, a proper UV light for resin is recommended.

4. How long does it take for epoxy resin to cure under UV light?

Epoxy resin does not cure effectively under UV light. Only UV resin hardens under UV exposure, typically within 30 seconds to a few minutes, depending on intensity and layer thickness.

5. Are dual-wavelength UV lights better for resin?

Yes, dual-wavelength lamps (365nm + 405nm) work with more types of UV resin and ensure even curing, faster results, and fewer soft spots, making them ideal for larger or complex projects.

6. Is a high-intensity UV light better for resin?

A higher-intensity UV lamp (measured in mW/cm²) cures resin faster and allows thicker pours to harden evenly. However, adjustable intensity settings are helpful to prevent overheating or over-curing delicate pieces.

7. Can UV nail lamps be used for resin?

Yes, UV nail lamps can cure UV resin, provided the wavelength matches the resin’s requirements. They are a good budget-friendly option for small projects like jewellery or charms.