1. Introduction

When planning a garage upgrade, understanding the cost of epoxy garage floor is essential. Prices can vary widely depending on materials, labour, garage size, and optional features. In this guide, we break down all the factors that affect pricing, compare epoxy to other flooring options, and provide tips to get the best value for your investment.

Table of Contents

2. Average Cost of Epoxy Garage Floor Per Square Foot & Total Cost

The cost of epoxy garage floor usually ranges between $3 to $12 per square foot, depending on the quality of materials, the condition of the concrete, and whether you choose DIY or professional installation. For most homeowners, the total cost falls between $1,000 and $6,000, with the size of the garage being the biggest factor. A basic water-based epoxy coating is generally the cheapest option, while high-solids or decorative systems such as metallic or flake epoxy can be more expensive but offer better durability and appearance. Labour costs also add to the overall price, especially for multi-layer systems that require grinding or repairing the concrete before application.

Below is a simple breakdown to help you understand average pricing:

1-Car Garage (200–300 sq. ft.): $800 – $2,500

2-Car Garage (400–500 sq. ft.): $1,500 – $4,500

3-Car Garage (600–700 sq. ft.): $2,500 – $6,000+

These prices include both materials and installation. If you choose to do it yourself, the cost may be lower, but you must factor in tools, equipment rental, and preparation materials. Knowing the average price range helps you budget realistically and compare different epoxy systems before making a decision.

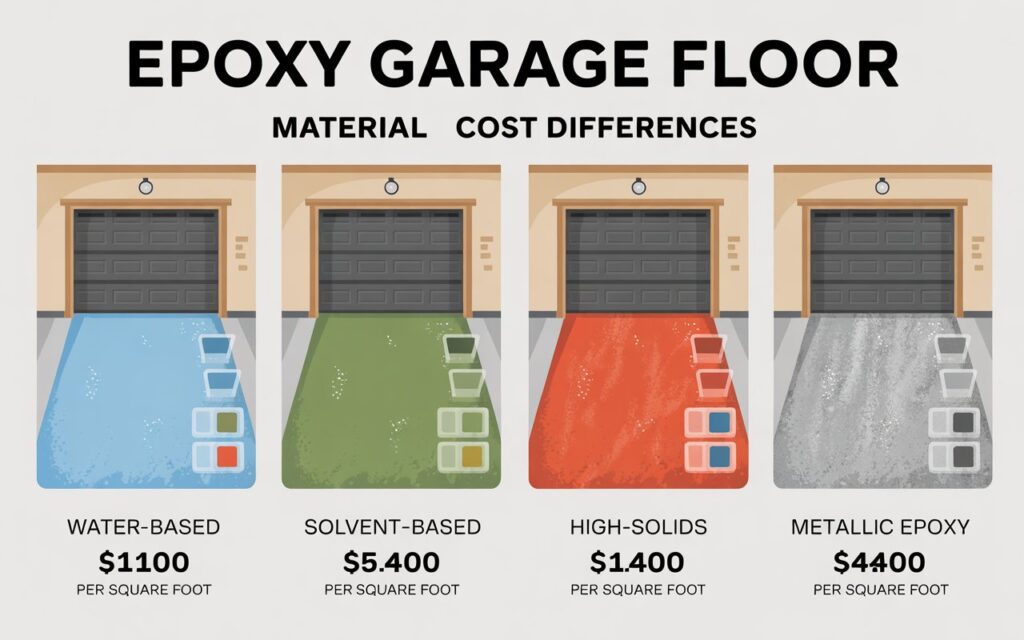

3. Material Types & Their Cost Differences

The cost of epoxy garage floor depends heavily on the type of epoxy material you choose. Each material has its own price range, durability level, and appearance. Understanding these differences will help you select the right option for your garage and budget.

1. Water-Based Epoxy

Water-based epoxy is the most affordable option. It is easy to apply and ideal for DIY projects.

Cost: $2 to $5 per sq. ft.

Pros: Low odor, simple application, budget-friendly.

Cons: Thin coating, less durable compared to other types.

2. Solvent-Based Epoxy

Solvent-based epoxy creates a stronger bond with the concrete and offers better durability.

Cost: $4 to $8 per sq. ft.

Pros: Harder finish, resistant to stains and chemicals.

Cons: Strong fumes, requires proper ventilation during installation.

3. High-Solids Epoxy

High-solids epoxy is the premium grade option used by many professionals. It creates a thick, long-lasting finish that holds up well under heavy use.

Cost: $6 to $12 per sq. ft.

Pros: Extremely durable, thicker coating, long lifespan.

Cons: Higher cost and usually requires professional installation.

4. Metallic Epoxy

Metallic epoxy is known for its decorative, 3D appearance. It is popular for homeowners who want a unique, high-end look.

Cost: $8 to $15+ per sq. ft.

Pros: Beautiful finish, customizable designs, premium appearance.

Cons: Expensive and requires skilled installers.

5. Epoxy With Decorative Flakes

Flake epoxy includes colored flakes for texture, traction, and style.

Cost: $5 to $10 per sq. ft.

Pros: Slip-resistant, hides imperfections, customisation colour blends.

Cons: Costs more than basic epoxy systems.

Choosing the right material depends on your budget, the condition of your garage floor, and the look you want to achieve. Higher-end epoxy systems cost more upfront but typically last longer and offer better performance.

4. Labour Costs: DIY vs. Professional Installation

Labour is one of the biggest factors that affects the cost of epoxy garage floor. Many homeowners wonder whether they should install the epoxy themselves or hire a professional. Both options have different price ranges, benefits, and limitations. Understanding these differences will help you choose the method that fits your budget and expectation.

DIY Epoxy Installation

DIY kits are widely available and affordable, making them a popular choice for smaller garages or simple projects.

Average Cost: $100 – $600 for materials

Estimated Cost Per Sq. Ft.: $1 – $3

Pros:

Lowest upfront cost

Good for basic floors

Suitable for small repairs and light use

Cons:

Results depend on skill level

Often less durable

Requires tools, concrete prep, and time

Mistakes can be expensive to fix

DIY epoxy is a good option if you have experience with concrete coatings and your garage floor is in good condition. However, for heavily damaged floors or decorative finishes, DIY may not provide professional-level results

Professional Epoxy Installation

Hiring a professional creates a stronger, thicker, and more durable finish. Professionals also handle surface preparation, which is crucial for long-term performance.

Average Cost: $3 – $12 per sq. ft.

Total Cost Range: $1,000 – $6,000+ depending on garage size

Pros:

High-quality and long-lasting results

Expert surface preparation

Access to commercial-grade epoxy products

Ideal for metallic, flake, or high-solids systems

Cons:

Higher upfront cost

Scheduling may take time

Professional installation is the best choice when you want a flawless finish, maximum durability, or advanced epoxy design.

Which Option Is Best for You?

If your priority is saving money, DIY is the cheaper route. But if you want a long-lasting finish that can handle heavy vehicles, stains, and wear, hiring a professional offers better value over time. In most cases, the added quality justifies the higher cost of epoxy garage floor installed by an expert.

5. Surface Preparation & How It Impacts the Cost

Surface preparation is one of the most important steps in epoxy installation, and it has a significant impact on the cost of epoxy garage floor. Before epoxy can be applied, the concrete must be properly cleaned, repaired, and profiled so the coating bonds correctly. The amount of prep needed depends on the age and condition of your floor.

Why Surface Preparation Matters

Proper surface prep ensures:

Strong adhesion between epoxy and concrete

Reduced risk of peeling, bubbling, or early failure

A smoother, more professional-looking finish

Longer lifespan of the epoxy coating

If the concrete is dirty, cracked, or uneven, the epoxy will not bond well, which can lead to costly problems later.

Common Types of Surface Preparation

1. Cleaning and Decreasing

Oil stains, dirt, and chemicals must be removed completely. If the surface is contaminated, epoxy won’t adhere properly.

Impact on cost: Light cleaning adds a small cost; heavy degreasing adds more.

2. Crack Repair and Patching

Holes, cracks, and pitting must be filled before coating. Damaged floors need more materials and labor.

Impact on cost: Minor cracks are inexpensive to fix, while deep repairs increase the overall cost significantly.

3. Grinding or Etching the Concrete

To help the epoxy bond, professionals grind the surface or use acid etching to create a textured profile.

Impact on cost: Grinding is more expensive than etching but provides better long-term results.

4. Moisture Testing and Prevention

Moisture under the concrete can cause epoxy to lift or bubble. Testing and adding a moisture barrier may be necessary.

Impact on cost: A moisture barrier adds to the total price but prevents future failures.

How Prep Costs Affect the Final Price

The more repairs and preparation your floor needs, the higher the cost of epoxy garage floor will be. A floor in good condition may need only basic cleaning and light grinding. In contrast, older or heavily stained floors may require deep grinding, patching, and moisture treatment, which increases the overall cost.

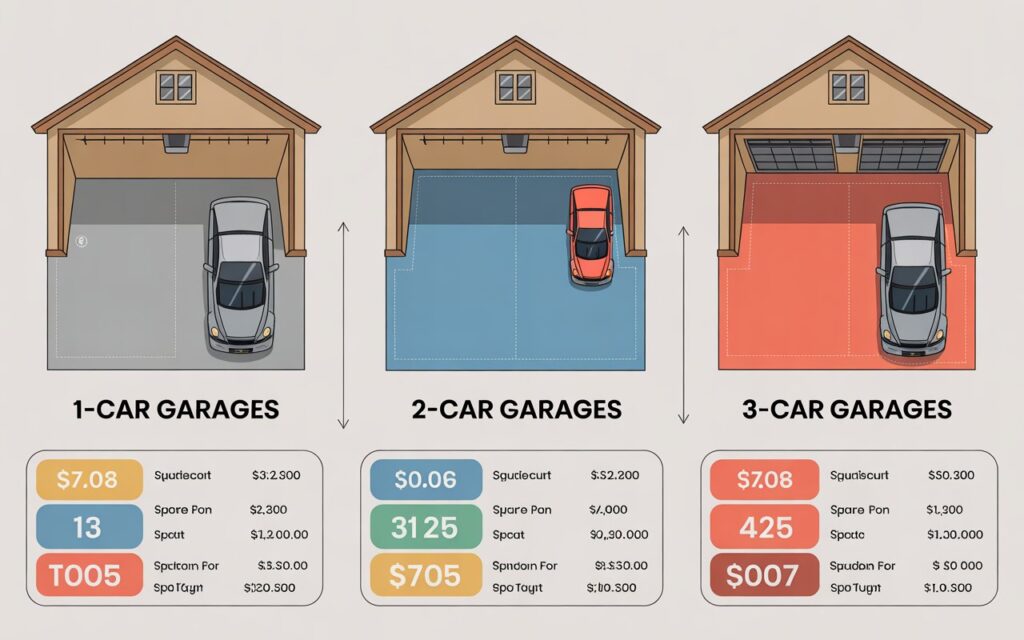

6. Garage Size & Layout Cost Comparison

Garage size is one of the biggest factors that determines the overall cost of epoxy garage floor. Since epoxy flooring is usually priced per square foot, larger garages naturally require more materials, more labor, and more preparation time. The layout of the garage can also influence the final price, especially if the space includes curves, steps, or tight corners.

How Garage Size Impacts Total Cost

Below is a simple breakdown of what homeowners can expect to pay based on common garage sizes:

1-Car Garage (200–300 sq. ft.)

A 1-car garage is the smallest and most affordable option.

Estimated Cost: $800 – $2,500

Why: Less surface area, fewer materials, and minimal labor time.

2-Car Garage (400–500 sq. ft.)

This is the most common garage size.

Estimated Cost: $1,500 – $4,500

Why: More prep work, larger material usage, and usually more cracks or stains to repair.

3-Car Garage (600–700 sq. ft.)

Larger spaces require more effort and higher-quality equipment.

Estimated Cost: $2,500 – $6,000+

Why: More grinding, more coating layers, and longer installation hours.

How Layout Affects the Cost

Even if two garages have the same size, their layouts can make the total price very different:

1. Uneven or Sloped Floors

Sloped or uneven concrete may need extra leveling before epoxy can be applied.

2. Steps, Storage Areas, or Built-In Structures

These require precise edging, cutting in, and extra coating time.

3. Narrow Corners and Tight Edges

Spaces with many corners or obstructions increase labor time, which affects price.

4. Multiple Rooms or Divided Spaces

Some garages include side rooms, workshops, or utility areas. Coating these areas adds to the total square footage and installation time.

Why Size and Layout Matter for Cost

The cost of epoxy garage floor depends on more than just materials. Large or complex garages require more:

Labor hours

Surface preparation

Epoxy layers

Tools and equipment. This is why two homes may receive very different quotes even if the square footage seems similar.

7. Additional Features & Add-On Costs

When calculating the cost of epoxy garage floor, it’s important to consider the extra features and upgrades you may want. These add-one can enhance durability, improve appearance, or offer better long-term protection but they also increase the total price. Understanding these optional features will help you build a more accurate budget.

1. Decorative Colour Flakes

Color flakes are one of the most popular upgrades. They add texture, improve traction, and help hide imperfections in the concrete.

Added Cost: $0.50 – $1.50 per sq. ft.

Why Choose It: Creates a more attractive, custom finish that looks professional.

2. Metallic Epoxy Effects

Metallic epoxy creates a smooth, glossy, 3D effect that stands out compared to standard coatings.

Added Cost: $3 – $7+ per sq. ft.

Why Choose It: Makes the garage look modern and high-end.

3. Anti-Slip Additives

Anti-slip materials such as silica sand or grit can be mixed into the topcoat.

Added Cost: $0.30 – $1.00 per sq. ft.

Why Choose It: Adds safety, especially in garages exposed to water, snow, or oil.

4. UV-Resistant Topcoat

A UV-stable topcoat prevents yellowing and fading caused by sunlight.

Added Cost: $0.50 – $2.00 per sq. ft.

Why Choose It: Essential if the garage receives direct sunlight or if doors stay open frequently.

5. Moisture Barrier Layer

A moisture barrier is applied when the concrete has high humidity levels or moisture issues.

Added Cost: $1.00 – $3.00 per sq. ft.

Why Choose It: Prevents peeling, bubbling, and long-term coating failure.

6. Extra Epoxy Layers

Some homeowners prefer adding extra layers for added durability especially if the garage is used as a workshop or storage space.

Added Cost: $1.50 – $4.00 per sq. ft.

Why Choose It: Improves hardness, durability, and resistance to chemicals.

7. Custom Borders or Designs

Decorative stripes, borders, or patterns can be added to create a unique look.

Added Cost: Varies depending on complexity

Why Choose It: Ideal for custom garages, car showrooms, or premium home finishes.

Bottom Line

These add-one can increase both the performance and the beauty of your floor. While they do raise the cost of epoxy garage floor, many homeowners find the upgrades worthwhile especially when they want a long-lasting, visually appealing finish.

8. Durability & Longevity: Cost vs. Life Expectancy

When evaluating the cost of epoxy garage floor, it’s important to consider not just the upfront price, but also how long the floor will last. Durability and life expectancy directly influence the overall value of your investment. A higher-quality epoxy system may cost more initially but can save money in the long run by reducing maintenance and replacement needs.

How Durability Affects Cost

Epoxy floors vary in thickness, chemical resistance, and wear tolerance. Thicker coatings and higher-grade epoxy materials generally last longer but are more expensive. For example:

Water-based epoxy: Affordable but thinner; lasts 3–5 years under normal use.

Solvent-based epoxy: Moderately priced; lasts 5–7 years with proper care.

High-solids or industrial-grade epoxy: Higher cost; can last 10–20 years or more.

Metallic or decorative epoxy: Expensive, but extremely durable if installed professionally.

Choosing a cheaper epoxy may save money upfront but could lead to peeling, chipping, or fading, requiring early replacement and increasing long-term costs.

Factors That Influence Longevity

Traffic and Usage

Heavily used garages with cars, tools, or equipment experience more wear. Higher-traffic areas benefit from thicker, premium epoxy layers.

Surface Preparation

Proper preparation ensures the epoxy bonds correctly. Poor prep reduces adhesion and shortens life expectancy.

Maintenance

Regular cleaning and occasional re-coating of high-wear areas prolong durability.

Environmental Factors

Exposure to sunlight, water, or chemicals can affect epoxy. UV-resistant topcoats and moisture barriers help protect the surface.

Balancing Cost and Longevity

When calculating the cost of an epoxy garage floor, think in terms of long-term value:

Lower-cost epoxy: Cheaper upfront, shorter lifespan, may need replacement sooner.

Premium epoxy: Higher upfront cost but fewer repairs, longer life, and better aesthetics. Ultimately, investing in a high-quality system can be more cost-effective over the lifetime of your floor.

9. Maintenance Costs & Long-Term Savings

When evaluating the cost of epoxy garage floor, it’s important to consider maintenance and long-term savings. While epoxy floors require some care, they are relatively low-maintenance compared to other flooring options. Proper upkeep can extend the life of your floor, protect your investment, and reduce future costs.

Routine Maintenance

Epoxy floors are durable and resistant to stains, chemicals, and moisture, but regular maintenance is necessary to keep them in top condition:

Sweeping and Dusting: Daily or weekly removal of dirt and debris prevents scratches and wear.

Mopping: Use mild detergents or a solution of water and vinegar to clean spills and stains.

Spot Repairs: Small chips or scratches can be filled with epoxy repair kits, usually at minimal cost.

Estimated Maintenance Cost: $50–$150 per year for cleaning supplies and minor repairs.

Periodic Re-Coating

Depending on traffic and wear, a fresh topcoat may be needed every 3–5 years. This protects the epoxy from fading, chipping, or peeling.

Cost of Re-Coating: $1–$3 per sq. ft., significantly lower than a full replacement

Long-Term Savings Compared to Other Flooring Options

Epoxy floors may cost more upfront than basic concrete staining or paint, but they save money over time:

Durability: Resistant to oil, chemicals, and heavy vehicles, reducing the need for frequent repairs.

Longevity: High-quality epoxy lasts 10–20 years, avoiding replacement costs.

Low Maintenance: Simple cleaning methods reduce labor and cleaning product expenses.

Enhanced Value: A professionally finished epoxy floor adds aesthetic appeal and resale value to your home.

By considering maintenance and long-term savings, the cost of epoxy garage floor becomes more reasonable. Investing in quality epoxy and proper care ensures you get maximum value over time.

10. Cost Comparison: Epoxy vs. Other Garage Flooring Options

When planning a garage renovation, it’s helpful to compare the cost of epoxy garage floor with alternative flooring options. This allows homeowners to make informed decisions based on budget, durability, and maintenance requirements.

1. Epoxy Flooring

Cost: $3 – $12 per sq. ft.

Pros: Highly durable, chemical-resistant, low maintenance, customizable finishes (flakes, metallic, or solid colors).

Cons: Requires proper surface preparation; professional installation can increase upfront costs.

Lifespan: 10–20 years with proper care.

2. Concrete Stain

Cost: $2 – $6 per sq. ft.

Pros: Affordable, easy to apply, provides a decorative finish.

Cons: Less durable, prone to chipping or fading, requires frequent resealing.

Lifespan: 3–7 years before major touch-ups or reapplication.

3. Garage Floor Tiles

Cost: $4 – $15 per sq. ft.

Pros: Quick installation, removable and replaceable tiles, variety of colors and patterns.

Cons: Can trap dirt underneath, less chemical and impact resistance, may shift over time.

Lifespan: 5–15 years depending on quality and traffic.

4. Polyurethane Coatings

Cost: $6 – $12 per sq. ft.

Pros: UV-resistant, flexible, smooth finish, chemical and abrasion-resistant.

Cons: Higher material cost, professional installation recommended, less decorative options compared to epoxy.

Lifespan: 10–15 years.

5. Vinyl Flooring or Roll-Out Mats

Cost: $3 – $10 per sq. ft.

Pros: Easy DIY installation, slip-resistant, inexpensive short-term option.

Cons: Less durable, prone to tears, chemical staining, or shifting.

Lifespan: 5–10 years.

Key Takeaways

While some alternatives may have lower upfront costs, the cost of epoxy garage floor often provides the best long-term value due to durability, low maintenance, and lifespan. Epoxy is especially beneficial for homeowners with high-traffic garages, chemical exposure, or those seeking a professional and polished finish. When factoring in maintenance, repairs, and longevity, epoxy frequently becomes the most cost-effective and practical choice over time.

11. Regional Pricing Differences

The cost of epoxy garage floor can vary depending on your location. Labour rates, material availability, and local demand all influence pricing. Understanding regional differences helps homeowners budget more accurately and find competitive quotes.

1. Labour Costs by Region

Labor is a major component of epoxy flooring costs. In some states or metropolitan areas, professional installers charge more due to higher wages or cost of living.

High-Cost Areas: California, New York, Massachusetts – labor can add $4–$8 per sq. ft.

Medium-Cost Areas: Texas, Florida, Illinois – labor typically adds $3–$6 per sq. ft.

Low-Cost Areas: Midwest and smaller towns labour may be $2–$4 per sq. ft.

2. Material Availability

Some regions have limited suppliers for high-quality epoxy products, which can increase material costs. Urban areas often have easier access to premium or speciality epoxies, whereas rural locations may rely on standard options, affecting both cost and variety.

3. Seasonal Demand

In colder regions, epoxy installation may be limited to warmer months, which can increase seasonal pricing. Contractors may charge more during peak months when demand is high.

4. Local Regulations and Taxes

Local building codes, permit requirements, and sales tax can influence total costs. Some cities require special ventilation or preparation standards for chemical coatings, adding to labour and material expenses.

5. Regional Cost Summary

Here’s an approximate guide to average cost of epoxy garage floor costs across regions in the U.S.:

| Region | Avg. Cost per sq. ft. | Notes |

| Northeast | $5 – $12 | Higher labor rates, dense urban areas |

| West Coast | $6 – $12 | High demand, premium materials common |

| Midwest | $3 – $8 | Lower labor costs, standard materials |

| South | $4 – $9 | Moderate labor costs, good availability |

Key Takeaways

Geographic location significantly impacts the cost of epoxy garage floor.

Homeowners in high-cost regions should budget extra for labour and material availability.Comparing local contractors and material suppliers can help find the best balance between price and quality.

12. Hidden Costs You Should Know

When planning your garage upgrade, it’s important to account for more than the basic materials and installation. Several hidden factors can influence the cost of epoxy garage floor. Ignoring these can result in unexpected expenses and delays, so understanding them upfront will help you budget accurately.

1. Concrete Repairs

Cracks, chips, or pitting in the concrete often need to be repaired before applying epoxy. Extensive repairs can add several hundred dollars or more, depending on the severity of the damage.

2. Moisture Mitigation

High moisture levels in concrete can cause bubbling or peeling. Installing a moisture barrier or primer may be necessary, adding extra cost.

3. Surface Preparation

Even if your garage looks clean, grinding, etching, or removing old coatings may be required to ensure proper adhesion. These prep steps can significantly increase labour and material costs.

4. Extra Layers and Add-Ons

Decorative flakes, metallic finishes, anti-slip additives, or UV-resistant topcoats improve durability and aesthetics but increase overall cost. Each optional layer adds material and labour expenses.

5. Tools and Equipment

For DIY installations, you may need to rent grinders, rollers, squeegees, or other tools. Even professional installations include equipment costs in the labour charge.

6. Waste and Overages

Some epoxy kits or materials may not cover exactly the estimated area. Extra epoxy, primer, or topcoat may be required, especially for complex garage layouts.

7. Unexpected Labor

Obstacles such as tight corners, storage areas, built-in shelves, or garage steps can increase installation time, raising labour costs beyond the initial quote.

Key Takeaways

Hidden costs can add 10–30% or more to the basic estimate. To avoid surprises:

Get a detailed breakdown of material, labor, and prep costs.

Inspect your concrete thoroughly to identify repair needs.

Factor in optional features, surface prep, and potential overages.

By planning for these hidden expenses, you can better understand the cost of an epoxy garage floor and avoid unexpected financial strain.

13. Final Cost Breakdown Table (Example)

After exploring all the factors that influence the cost of epoxy garage floor, it’s helpful to summarise the typical expenses in a clear table. This gives homeowners a realistic estimate of what to expect based on garage size, material choice, tabor, and optional add-nos.

Example Cost Breakdown

| Cost Component | Description | Estimated Price per sq. ft. | Notes |

| Materials (Epoxy) | Basic water-based epoxy | $2 – $5 | DIY or professional |

| Labor | Professional installation | $3 – $8 | Depends on region and complexity |

| Surface Preparation | Cleaning, grinding, crack repair | $1 – $5 | Varies with floor condition |

| Decorative Add-Ons | Flakes, metallic, anti-slip | $0.50 – $3 | Optional upgrades |

| Moisture Barrier | Required for damp concrete | $1 – $3 | Only if needed |

| Extra Layers / Topcoat | Enhances durability | $1.50 – $4 | Optional for high-traffic garages |

| Hidden Costs | Tools, waste, unexpected labor | $0.50 – $2 | Plan 10–20% extra |

Total Cost Examples by Garage Size

| Garage Size | Approx. Total Cost Range | Notes |

| 1-Car (200–300 sq. ft.) | $800 – $2,500 | Small, simple layout |

| 2-Car (400–500 sq. ft.) | $1,500 – $4,500 | Average household garage |

| 3-Car (600–700 sq. ft.) | $2,500 – $6,000+ | Larger space with potential add-ons |

Key Takeaways

The cost of epoxy garage floor is influenced by material quality, tabor preparation, and optional upgrades.Planning for hidden costs and optional features ensures your budget is accurate. Investing in proper preparation and high-quality epoxy can reduce long-term expenses and maintenance.

14. Conclusion

Understanding the cost of an epoxy garage floor is essential for homeowners planning a garage upgrade. Multiple factors including material type, labour, surface preparation, garage size, layout, optional features, and regional pricing can all impact the final price. By considering these elements upfront, you can avoid unexpected expenses and make informed decisions that balance cost, durability, and appearance.

Epoxy flooring offers long-term value due to its durability, low maintenance, and attractive finish. While upfront costs may be higher than other flooring options, investing in high-quality materials and proper installation can save money over time by reducing repairs, maintenance, and replacement needs. Optional upgrades such as decorative flakes, metallic finishes, anti-slip additives, and UV-resistant coatings allow homeowners to customize their floors while enhancing functionality and aesthetics.

Proper planning, understanding hidden costs, and comparing local contractors are key steps to ensuring you get the best value. With the right approach, your epoxy garage floor will not only enhance the appearance of your garage but also provide a long-lasting, cost-effective solution.

FAQs

1. How much does an epoxy garage floor cost per square foot?

$3 – $12 per sq. ft., depending on materials, labour, and add-one.

2. Why does the cost vary?

Factors include epoxy type, garage size, surface prep, labour rates, and optional upgrades.

3. Is DIY installation cheaper than hiring a professional?

Yes, DIY can cost $1–$3 per sq. ft., but professionals ensure long-lasting results.

4. What hidden costs should I expect?

Concrete repairs, moisture barriers, extra layers, tools, and unexpected labor.

5. How does garage size affect cost?

1-car: $800–$2,500 | 2-car: $1,500–$4,500 | 3-car: $2,500–$6,000+

6. Are decorative finishes worth the extra cost?

Yes. Flakes, metallic coatings, and UV topcoats improve durability and appearance.

7. How long does an cost of epoxy garage floor last?

Water-based: 3–5 years | Solvent-based: 5–7 years | High-solids/metallic: 10–20 years

8. Does location affect cost?

Yes. Labour rates, material availability, and seasonal demand influence regional pricing.

9. What are the maintenance costs and long-term savings?

Maintenance is low. Investing in quality epoxy reduces future repairs. Garage epoxy floor price affects long-term savings.

10. How does epoxy compare to other garage flooring options?

Epoxy is durable and low-maintenance. Epoxy flooring cost per sq ft and epoxy floor materials determine value compared to alternatives.